When people hear “PVC,” most think of white plumbing pipes at the hardware store. But Polyvinyl Chloride is far more versatile than that — and in the machining world, it’s a reliable, high-performance plastic that’s easy to work with and surprisingly tough.

Whether you’re building components for water systems, electrical parts, chemical processing equipment, or even medical devices, PVC is worth a closer look. In this guide, we’ll walk through its properties, applications, machining tips, and how to get the best results.

What Is PVC?

PVC stands for Polyvinyl Chloride — a type of plastic that’s surprisingly tough, affordable, and incredibly versatile. If you’ve ever seen white plumbing pipes, electrical cable insulation, or even certain window frames, chances are you’ve seen PVC in action.

It’s made by combining vinyl chloride monomers into long chains, creating a strong yet lightweight material. One of the biggest reasons PVC is so popular is that it’s resistant to water, chemicals, and sunlight — meaning it doesn’t easily rust, corrode, or degrade.

PVC comes in two main types:

Rigid PVC (uPVC) – hard, strong, and used in things like pipes, building materials, and window frames.

Flexible PVC – made softer by adding plasticizers, perfect for things like hoses, cable insulation, and flooring.

Key Properties of PVC

Here’s why PVC is so popular in machining and manufacturing:

| Property | Benefit in Real-World Use |

| Corrosion resistance | Great for chemical plants, marine, and outdoor use |

| Chemical resistance | Handles acids, bases, and salts without degrading |

| Low moisture absorption | Maintains shape and stability in humid or wet conditions |

| High dielectric strength | Excellent for insulating electrical components |

| Flame retardancy | Naturally self-extinguishing |

| Abrasion resistance | Long-lasting in moving or abrasive environments |

| Lightweight but strong | Easier handling and lower transport costs |

Material Snapshot – PVC Gray Type 1

Density: ~1.38 g/cm³

Tensile strength: ~7,000 psi

Operating temperature: up to ~60°C (140°F) continuous

Good machinability with standard CNC tools

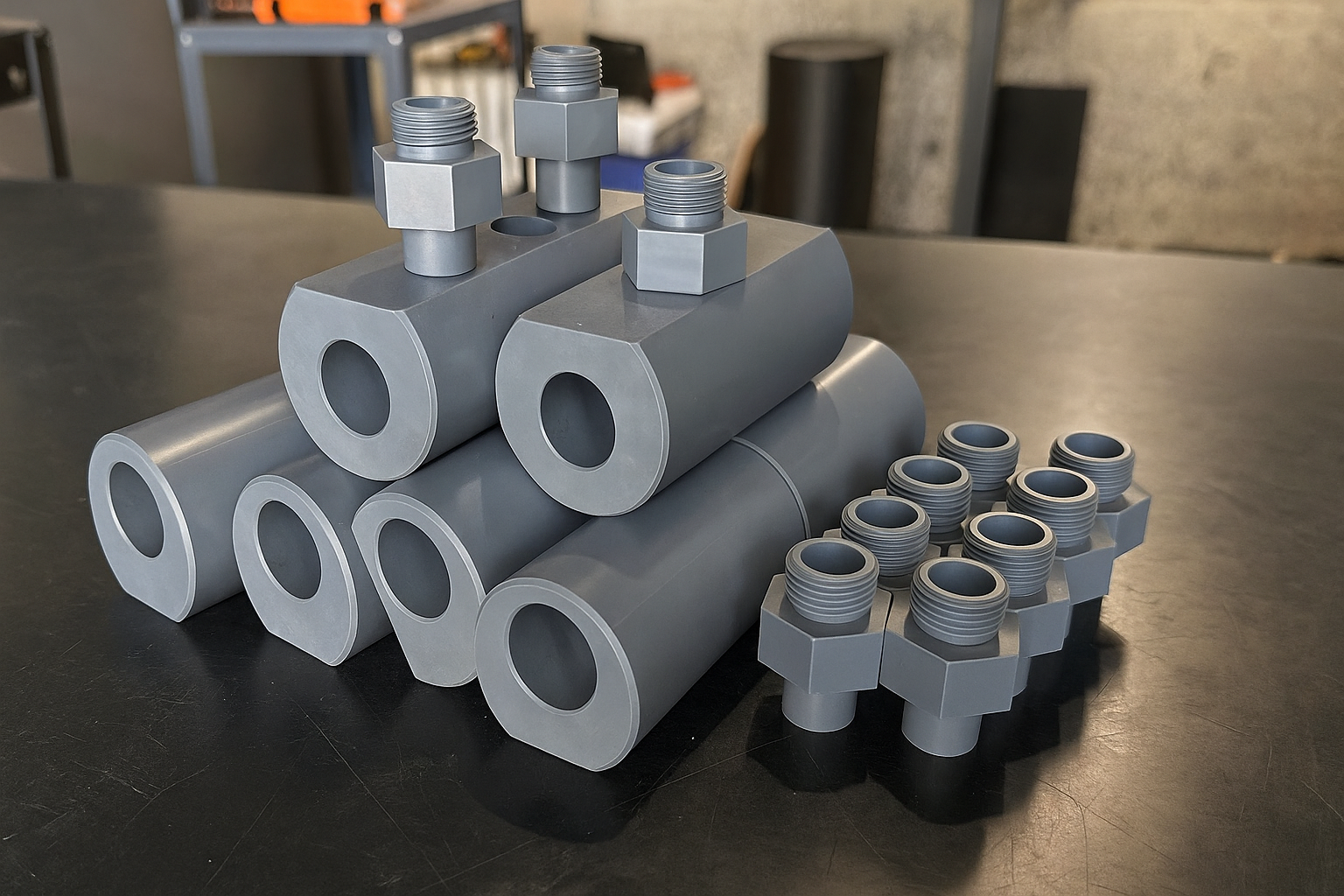

Where PVC Is Used ?

Here are some of the most common places you’ll find PVC:

Pipes and Plumbing – Probably the most famous use of PVC. Those white or gray pipes under sinks or in construction sites? Yep, that’s PVC, chosen for its resistance to corrosion and chemicals.

Electrical Cable Insulation – PVC keeps wires safe from moisture, heat, and damage, making it a favorite in both homes and industrial settings.

Building Materials – Think window frames, siding, roofing membranes, and even flooring. It’s strong enough to handle the elements.

Medical Equipment – Flexible PVC is used in things like IV tubes, blood bags, and oxygen masks because it’s safe, lightweight, and easy to sterilize.

Consumer Goods – From inflatable pool toys to credit cards, PVC sneaks into all sorts of products thanks to its versatility.

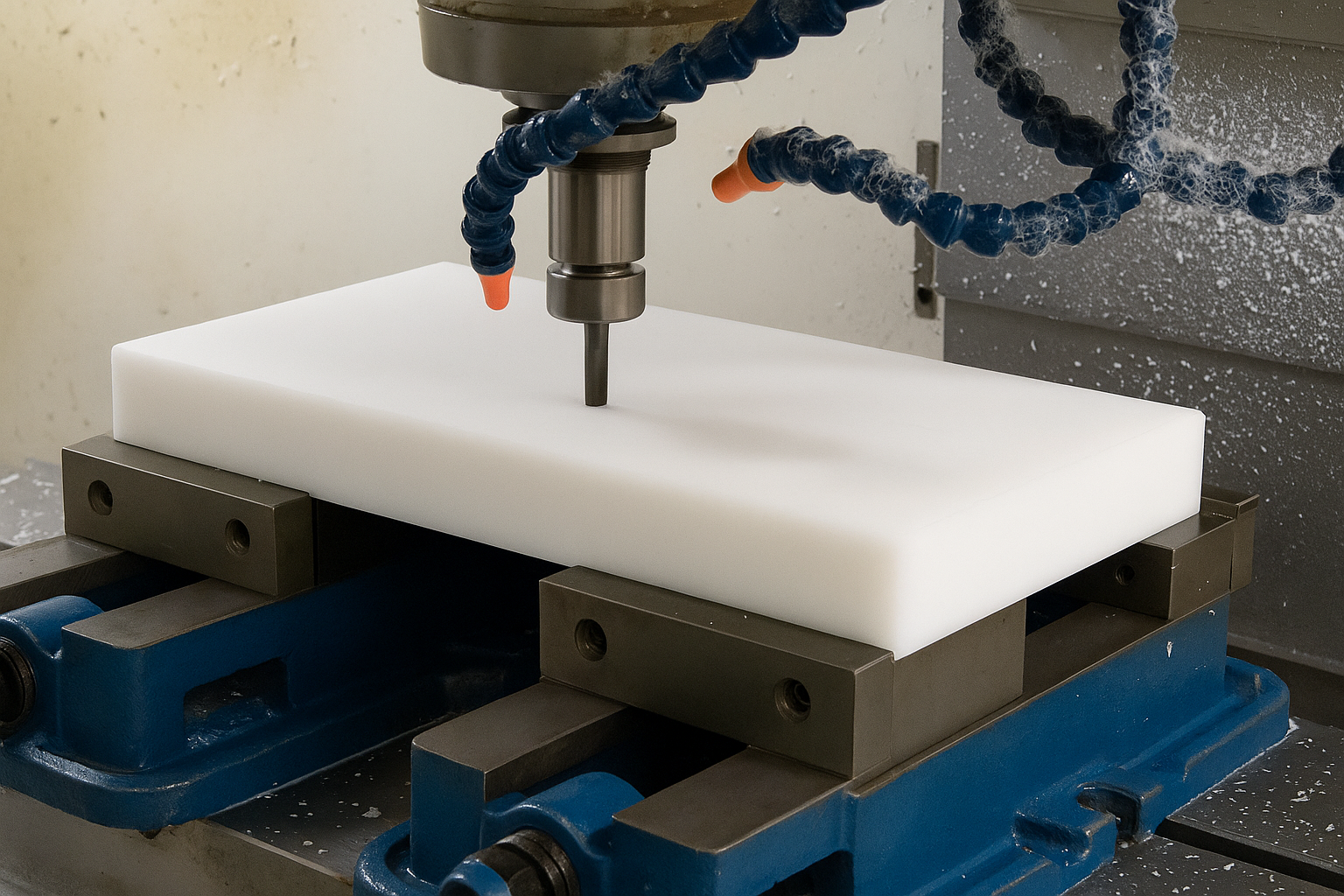

Key Techniques for Machining PVC

| Technique | How It Works | Why It Matters for PVC | Pro Tip |

| Use Sharp Cutting Tools | Choose carbide or HSS tools with a sharp edge. | PVC is soft enough to cut easily, but dull tools can crush it instead of slicing it. | Resharpen tools regularly to avoid rough edges. |

| Keep Speeds Moderate | Avoid extremely high spindle speeds. | High speed creates friction, which can heat up and melt PVC. | Aim for medium speeds and adjust feed rate to keep the chips flowing. |

| Support the Workpiece Well | Use clamps, vises, or fixtures to hold PVC securely. | PVC can vibrate or move under pressure, which can ruin accuracy. | Use soft jaws or padding to avoid clamp marks. |

| Prevent Overheating | Use air cooling or mist coolant. | Too much heat can cause PVC to warp or discolor. | Even a simple fan or compressed air can help. |

| Go for Light Passes | Take smaller depth cuts instead of removing too much at once. | Reduces tool pressure and avoids cracking or chipping. | Multiple light passes often produce a better finish. |

| Use the Right Drill Bits | Choose bits with a steeper point angle (60–90°). | This prevents the bit from grabbing and splitting the PVC. | Back the drill out occasionally to clear chips. |

| Finish with Sanding or Deburring | Lightly sand or scrape edges after machining. | Gives a smooth, safe, and professional finish. | Use fine-grit sandpaper for best results. |

Avoiding Contamination

One often-overlooked problem with machining plastics like PVC is cross-contamination. If a facility machines both metals and plastics in the same area, tiny metal particles can embed into PVC surfaces — leading to stress cracking or warping over time.

Solution: Use a dedicated plastic machining setup or work with a shop (like AIP) that specializes in all-plastic machining environments.

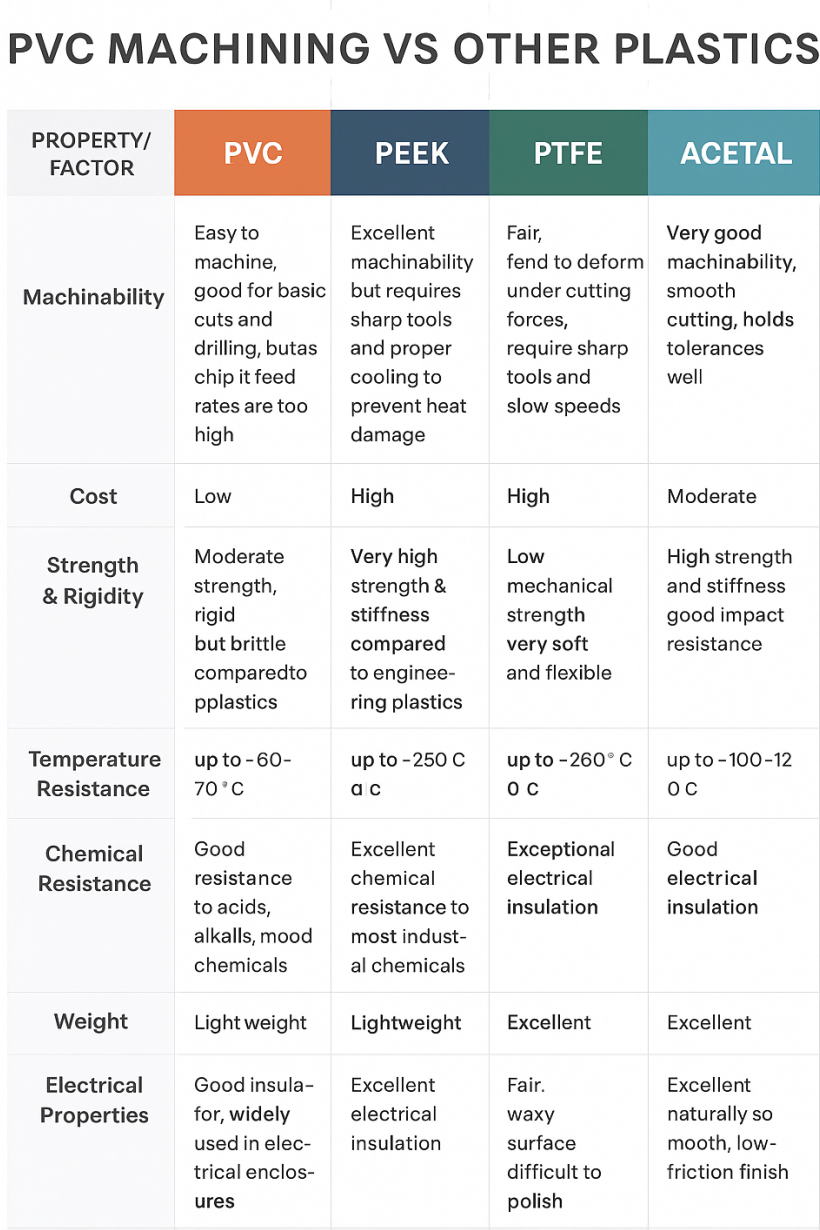

PVC Machining VS Other Plastics

Final Thoughts

PVC is a workhorse material: cost-effective, strong, and easy to machine when handled properly. If you anneal it, use sharp tools, keep your feeds and speeds reasonable, and protect it from contamination, you can produce precise, long-lasting parts for a wide range of applications.

For engineers and designers, the combination of chemical resistance, electrical insulation, and versatility makes PVC a smart choice for both prototypes and production.

FAQs

1. What is the difference between Rigid PVC (uPVC) and Flexible PVC?

Rigid PVC (uPVC), or unplasticized polyvinyl chloride, is hard, durable, and structurally strong. It is used in applications like plumbing pipes, window frames, and construction materials where rigidity and weather resistance are key. Flexible PVC is made by adding plasticizers to the compound, making it soft and pliable. It is used for applications requiring flexibility, such as hoses, medical tubing, and wire insulation.

2. Should I anneal PVC before machining, and why?

Yes, annealing (a heat treatment process) is recommended, especially for high-precision PVC components. PVC, like many plastics, can develop internal stresses during manufacturing (extrusion or molding). Annealing stabilizes the material by releasing these stresses, significantly reducing the risk of warping, cracking, or dimensional instability during and after the machining process.

3. Why is using sharp cutting tools so critical when machining PVC?

PVC is relatively soft. If you use dull tools, the tool edge will exert excessive pressure, tending to crush or push the material rather than cleanly slicing it. This action generates excessive heat, causes surface roughness (burrs), and can lead to immediate chipping or stress cracking in the finished part. Carbide or High-Speed Steel (HSS) tools must be kept extremely sharp.

4. What are the major hazards of cross-contamination when machining PVC?

Cross-contamination occurs when plastics are machined in an environment shared with metal fabrication. Tiny metal particles can become embedded in the soft PVC surface. These metal particles can act as stress points, potentially leading to chemical attack, stress cracking, or discoloration over time, especially when the PVC part is exposed to harsh chemicals or high stress in its intended use.

5. Can PVC handle high temperatures?

PVC has relatively poor high-temperature performance compared to materials like PEEK or PTFE. Standard rigid PVC (Type 1) typically has a maximum continuous operating temperature of around 60℃ (140℉). Machining must be done slowly, with cooling, to ensure the localized heat from the tool does not exceed this range and cause the material to melt or warp.

6. How does PVC compare to materials like Acrylic (PMMA) or HDPE in terms of strength and chemical resistance?

-

Compared to Acrylic: PVC is generally tougher and more shatter-resistant than Acrylic. PVC also offers superior chemical resistance across a broader range of chemicals. Acrylic, however, is optically clearer.

-

Compared to HDPE: PVC is significantly stronger and stiffer than HDPE. While HDPE has excellent chemical resistance, PVC also boasts high chemical resistance and is naturally flame retardant, a property HDPE lacks.

7. Why should I use air cooling instead of liquid coolant when machining PVC?

While liquid coolants are used for some plastics, PVC is often best machined using compressed air cooling or mist cooling. Air cooling effectively blows chips away while dissipating frictional heat. Using liquid coolant can sometimes lead to the coolant becoming trapped in the pores of the PVC, or if the shop also machines metal, the coolant could introduce metal particles, leading to contamination problems.

Read more: