We facilitate passivation and electropolishing, bead blasting, anodizing, and medical-grade finishing. They are applied to improve performance, sterilization, and surface smoothness for patient care.

Quality is at the core concern. We are certified to ISO 9001, and all articles/items are checked with the most updated measuring equipment. These ensure that all our stock components are made with accuracy in specifications and regulations before their arrival.

- Home

- Services

- CNC Machining

- Die Casting

- Mold Making

- Aluminum Die Casting

- Zinc Die Casting

- Magnesium Die Casting

- Die-cast Bracket Services

- Die-cast Enclosure Services

- Die-cast Housing Services

- Automotive Die Casting Services

- Gravity Die Casting Services

- Low-Pressure Die Casting Services

- China Diecasting Manufacturer

- High-Pressure Die Casting

- Prototype Die Casting Services

- High-Volume Die Casting Services

- Low-Volume Die Casting Services

- Sheet Metal Fabrication

- Plastic Injection Molding

- Contract Manufacturing

- Low Volume Manufacturing

- Massive Production

- Industries

- Automation

- Consumer Electronics

- Medical CNC Machining

- PCB Milling

- Aerospace Machining

- Automotive CNC Machining

- CNC Machined Bicycle Parts

- CNC Bottle Opener Machining

- CNC Camshaft Machining

- CNC Screw Machining

- CNC Machining Spare Parts

- CNC Piston Machining

- CNC Machined Gifts

- CNC Machined Fly Wheel

- CNC Machined Safety Razor

- CNC Machined Fidget Spinner

- CNC Machined Dice

- CNC Machined Chess Pieces

- Gallery

- Resources

- About Us

Medical CNC Machining

We manufacture complex medical components with micron-level precision—achieving tolerances as tight as ±0.002 mm.

Every part is produced under ISO 9001 certified processes, ensuring biocompatibility, consistency, and reliability.

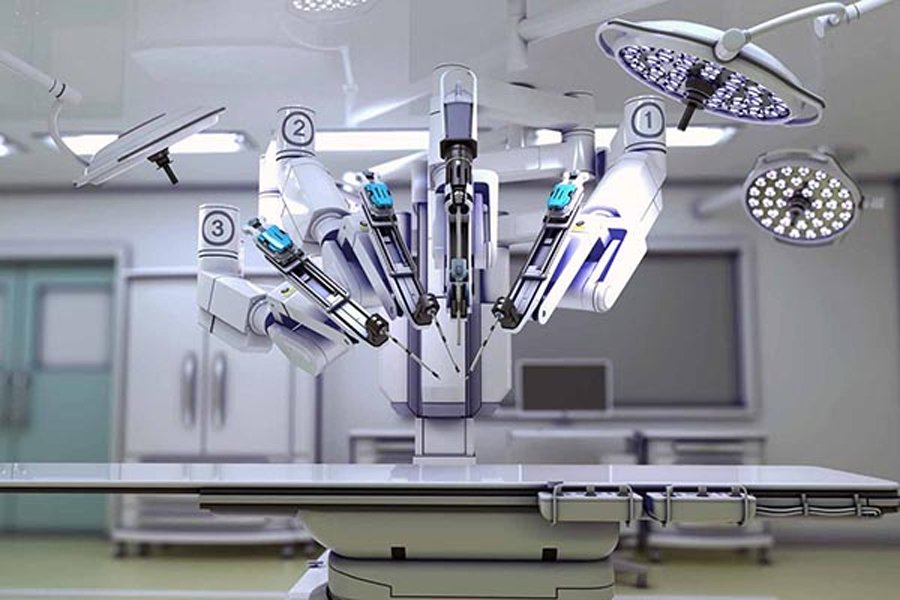

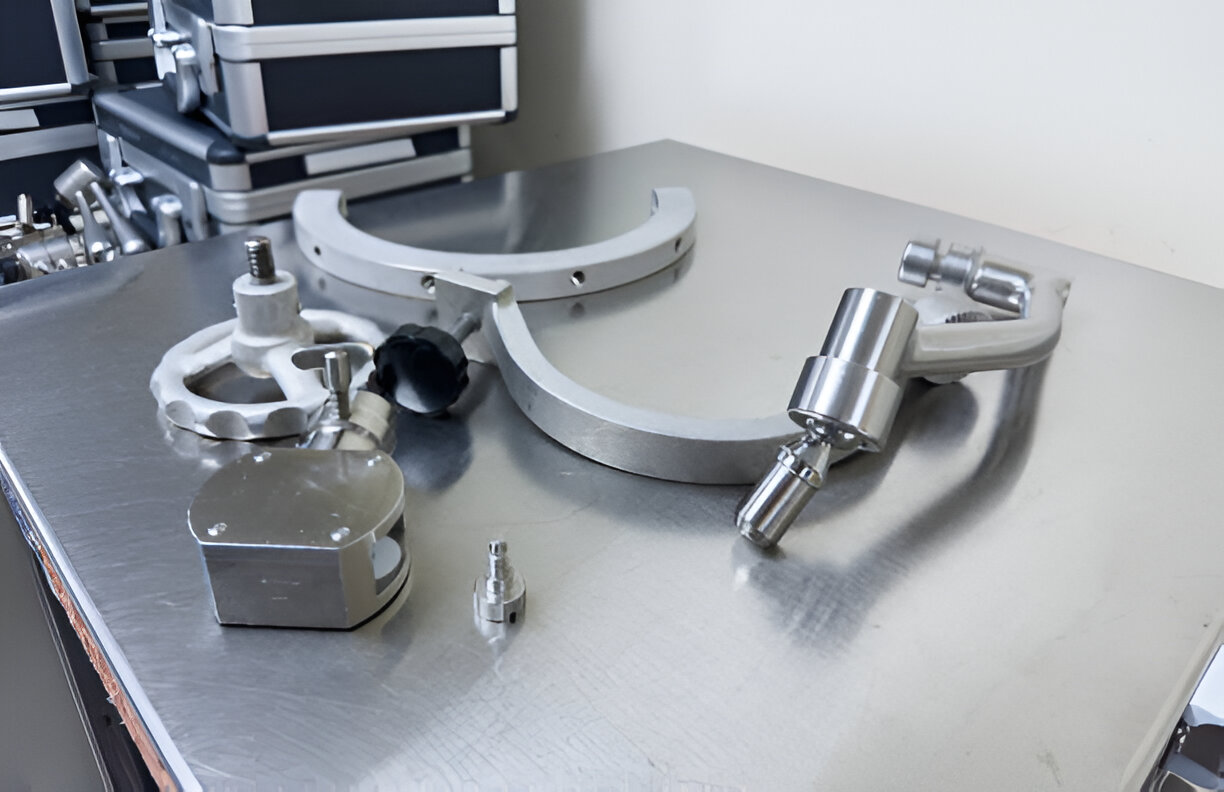

From surgical instruments to implantable devices, each piece is crafted with strict quality control and 100% inspection to meet the highest healthcare standards and support life-saving applications.

Send Your Inquiry Today

Our Medical Parts Machining Capabilities

Tops Precision uses superior materials, including stainless steel, titanium, aluminum, PEEK, Delrin, and medical plastics. These are selected based on the durability, corrosion resistance, and their biocompatibility to make sure that they conform to the medical device requirements.

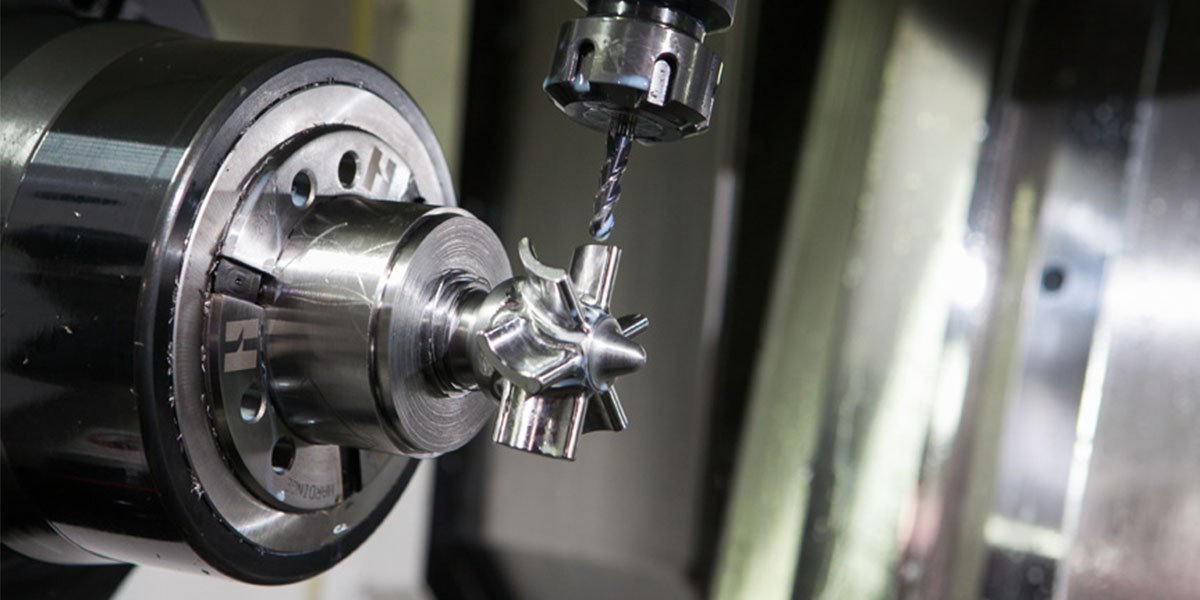

Our services are offered in a broad spectrum of machining services, i.e., CNC machining, precision turning, micro-drilling, and EDM. With such advanced technology, we can generate complex geometries, micro-fines, and small tolerances required in surgical equipment, implants, and diagnostic equipment.

Our Superior Rapid Prototyping Services for Medical Parts

Our prototyping is done quickly and accurately on medical parts to allow you to test and improve the design before complete production. We have a team that can handle sophisticated equipment to produce complex part designs to your project specifications.

It is possible to create prototypes with compatible with medical use, like lightweight titanium, strong stainless steel, and high-grade polymers. The individual pieces are cut and machined to the specifications of the necessary size and serve a purpose.

We provide performance-enhancing and aesthetic finishes on surfaces, such as smooth finishing and protective finishing. This allows the prototypes to be tried in real conditions.

Under a scrutinized process in all its stages, we make sure your prototypes are consistent and accurate. They come ready to be tested in practical settings.

Send Your Inquiry Today

Our Medical Device Manufacturing Techniques

We make medical devices with care and precision. Every part is made to meet strict safety and quality standards.

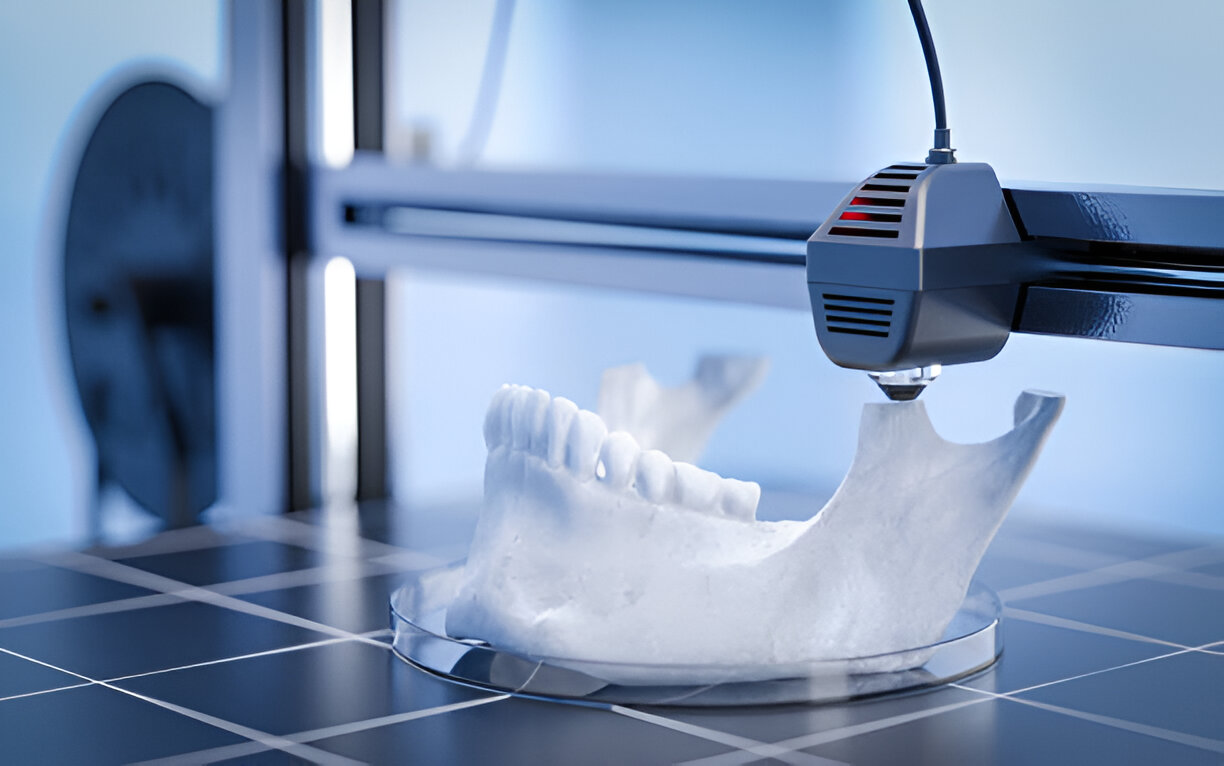

3D Printing

We start by converting your CAD designs into precise 3D models. Using medical-grade polymers or metal powders, we build components layer by layer with high resolution.

After printing, each part undergoes cleaning, support removal, surface smoothing, and dimensional verification to ensure it meets design specifications. This process is ideal for rapid prototyping, functional testing, and complex geometries. As these details and features are difficult to machine.

- Accuracy up to ±0.01 mm for detailed parts

- Cost-saving prototyping

- Fast production in just a few days

- Can make complex shapes easily

CNC Machining

We utilize CNC milling, turning, and micro-drilling on parts that demand the tightest of tolerances. The procedure starts with the right material choice, which may include titanium, stainless steel, and medical-grade plastics. Each part is machined to extreme precision, with attention to feed rates and cutting parameters to avoid work hardening or surface blemishes. Finish inspection monitors dimension, surface roughness, and mechanical integrity.

We offer

- Tolerances as tight as ±0.005 mm

- Efficient and affordable machining

- Quick turnaround for urgent parts

- Can handle complex designs

Sheet Metal Fabrication

Laser cutting, stamping, and precision press brakes cut, bend, and form sheet metal components. Depending on your application, we make use of medical-grade stainless steel or aluminium sheets. Once formed, the edges are deburred, surfaces polished, and assembled (where applicable). Construction and structural strength are confirmed, and each does fit all. We provide.

- Precise cutting, bending, and forming

- Low material waste for better cost control

- Fast production times

- Smooth and clean surfaces

Injection Molding

For high-volume plastic components, we create precision molds based on your design. Medical-grade polymers are injected under controlled temperature and pressure to allow 1000s of consistent parts to be made. Once cooled, parts are trimmed, polished, and checked for defects, warping, and dimensional deviations. Finished components can also undergo sterilization and surface finishing as per medical requirements.

- Consistent parts for high-volume production

- Low production costs

- Quick cycle times for fast delivery

- Smooth surfaces ready for sterilization

Send Your Inquiry Today

Why Choose Us for Medical Parts Manufacturing

Here are the facts, how we set ourselves apart from other competitors:

Cost-Effective Solutions

Our cost-effective production goes hand in hand with quality production of medical components. Through the organisation of every action, minimizing material waste, and efficient processes, we produce parts that are not only cost less but also precise and safe.

Completely Customised Components

Each project carries with it unique needs. We produce parts to your exact designs, either in a one-off prototype or series production. We collaborate with you very closely so that the parts are of exact dimensions, functional parameters, and material specifications.

Fast and Reliable Production

We know about the relevance of deadlines in the medical field. We have a lean operation, efficient machinery, and skilled personnel. This enables us to provide parts quickly without iterations later. Even our new generation equipment supports more complicated designs being done on time without compromising quality.

Strict Quality Control

Each component undergoes several verification processes to verify that it conforms to the requirements of ISO 13485 and ISO 9001. Surface finish, dimensions, and the integrity of the material are verified. So, all the components are safe, durable, and reliable to be used in important medical purposes.

Highly Precise and Accurate

Our tolerances and smooth finishes are kept very tight. This guarantees fit and part functions as required. Such high accuracy is key in surgical tools, implants, and diagnostic apparatus.

Regulatory Compliance

Our processes are synchronized with the rules and medical industry regulations. We have stringent protocols in place to make sure parts are safe, reliable, and fit to be used in the medical field, right down to our material selection to the final inspection.

High Technology and Innovation

All our manufacturing techniques are advanced, like 3D printing, CNC machining, sheet metal work, and injection molding. This allows us to manage complex geometries, functional test prototypes, and mass-scale production.

Cooperative and Client-friendly

Our manufacturing processes are changed to suit the particular needs of a project. It may be rapid prototyping, a low-volume specialty production run, mass manufacturing, or any combination in between. We make sure that your pieces get to you precisely as you need them.

Send Your Inquiry Today

Types of Medical Parts Machined for Medical Applications

We machine a wide variety of medical parts for different healthcare applications. Every component is designed for accuracy, durability, and safety.

Surgical Instruments

We manufacture scalpels, forceps, clamps, and other hand instruments used in surgeries. These components are fabricated using high-quality stainless steel, titanium to remain durable and able to withstand corrosion. All the instruments are smooth, accurate, and sterilized.

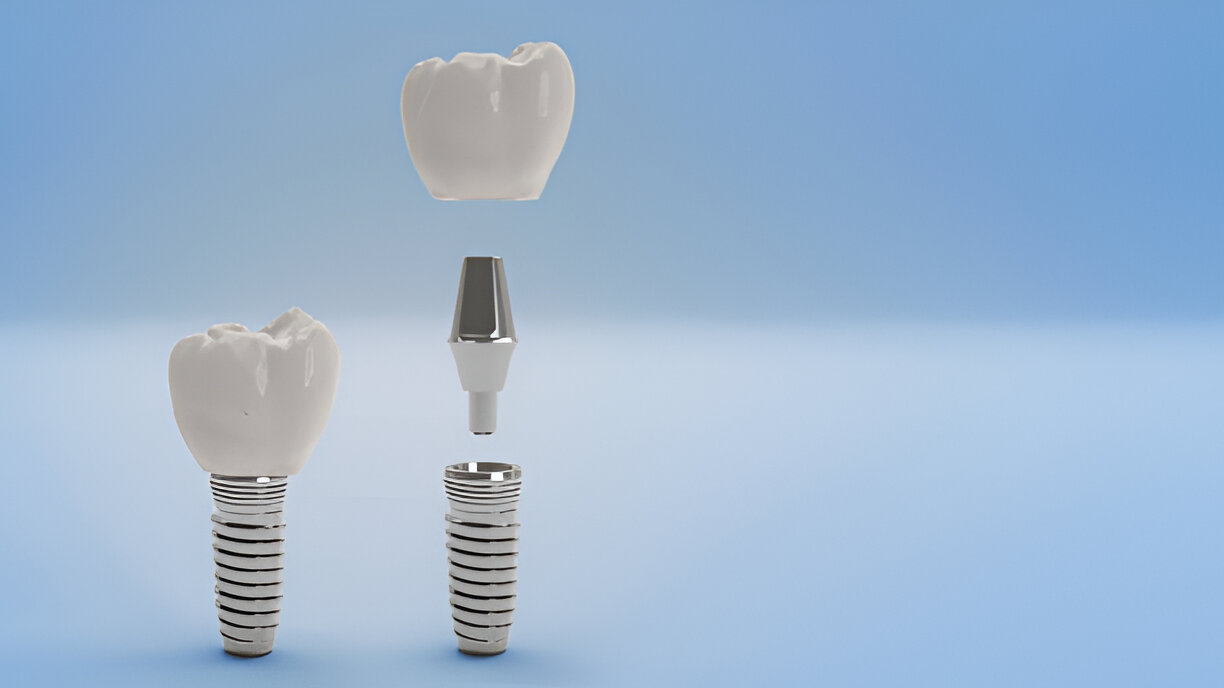

Prosthetics and Implants

We machine joint replacements, bone plates, screws, and dental implants. Biocompatibility is made with materials such as titanium and medical-grade polymers. Individual components are molded to fit and have durable performance.

Diagnostic and Imaging Components

We make components used in X-rays, MRI, and ultrasound. These include housings, brackets, and precision mounts. All the pieces are manufactured to close tolerances to ensure that they work reliably in sensitive equipment.

Medical Device Housings and Enclosures

We fabricate shielding protection cases and covers such as pacemakers, insulin pumps, and monitors. Such housings are safe, durable, and lead to a good fit between internal parts.

Laboratory Equipment Parts

Our products are machined parts of laboratory equipment such as centrifuges, pipettes, and test machines. Composites are marked to work accurately, repeatably, and be chemically resistant in laboratories.

Post-Processing for Medical Prototypes & Products

After making medical parts, we add finishing to make them strong, safe, and easy to clean. The type of finish depends on the material and use.

Finish Type | Description | Benefit |

Polishing | Smooths the surface | Easy to clean and sterilize |

Passivation | Treats stainless steel | Protects from rust |

Anodizing | Treats aluminum | Makes it stronger and durable |

Bead Blasting | Adds texture | Removes rough spots |

Medical Coatings | Protective layer | Safe for chemicals and sterilization |

These finishes make sure your parts last longer and are ready for medical use.

Send Your Inquiry Today

Frequently Asked Questions

We work with stainless steel, titanium, aluminum, PEEK, and other medical-grade plastics. These materials are chosen for strength, biocompatibility, and corrosion resistance.

Yes, we create parts according to your exact design and measurements. This includes prototypes, small batches, and full-scale production.

We use CNC machining, 3D printing, sheet metal fabrication, and plastic injection molding. Each method is chosen based on the part of your design complexity, material, and volume demands.

All parts are inspected at multiple stages. Our services are in line with ISO 13485 and ISO 9001 standards. We check dimensions, surface finish, and material integrity to ensure every component is safe and reliable.

Yes, our meticulous workflows and advanced equipment allow us to deliver prototypes and production parts quickly. So, you get parts made right without compromising accuracy and quality.

The medical world never stops evolving. With new innovations popping up daily, one thing that’s stayed consistently critical is precision. In the field of healthcare, there’s no room for mistakes—especially when it comes to the tools, implants, and components that go inside or work alongside the human body. That’s where Medical CNC Machining steps in.

CNC (Computer Numerical Control) machining isn’t just another manufacturing process—it’s a game-changer. It allows medical manufacturers to produce parts with incredible accuracy, down to the micrometer. Think surgical tools that need zero margin for error, or custom bone implants that must fit perfectly into a patient’s anatomy. With CNC machining, those aren’t just dreams—they’re a reality.

But why is CNC machining such a big deal in medicine? The answer lies in the level of control and repeatability it offers. By feeding precise instructions into a computer, machines can carve, cut, and shape even the toughest materials into flawless parts. And better yet, it’s super adaptable—you can switch between projects, customize designs on the fly, and scale up or down depending on demand.

In this guide, we’ll dive deep into how CNC machining works in the medical industry, what makes it unique, the materials involved, and what manufacturers need to consider. Whether you’re a medical device company, engineer, or just curious, this is your all-access pass to the high-precision world of medical CNC machining.

Why the Medical Industry Relies on CNC Machining

Let’s be real—healthcare products are held to the highest standards on the planet. From scalpels to spinal implants, every component needs to be spot-on. So, it’s no surprise the medical field leans heavily on CNC machining. But let’s unpack why this tech is such a perfect match.

Tight Tolerances are a Must

CNC machining can produce parts with tolerances as tight as ±0.01mm. That’s about one-fourth the width of a human hair! For things like surgical screws, bone plates, or catheter components, this kind of precision isn’t a luxury—it’s non-negotiable.

No Minimum Order Worries

Unlike other methods like injection molding, which require expensive tooling, CNC machining doesn’t have that barrier. So whether you need one custom knee implant or a thousand catheter clamps, CNC can handle both with ease. It’s perfect for low-volume, high-mix production.

Material Compatibility

From tough metals like titanium to medical-grade plastics like PEEK, CNC machines can work with a wide range of biocompatible materials. This means you’re not limited to just one or two materials—you’ve got options that suit both functionality and patient safety.

Fast Prototyping

Speed is everything when lives are on the line. CNC machining allows for rapid prototyping, so manufacturers can go from digital model to physical part in days—not weeks. That’s crucial in emergencies or product development cycles.

Consistency Every Time

CNC machines don’t get tired. They don’t guess or eyeball. Once programmed correctly, they produce identical parts again and again, reducing the risk of human error and maintaining the integrity of every batch.

In short, CNC machining offers the precision, flexibility, and speed the medical industry demands. It’s not just a good fit—it’s the backbone of modern medical manufacturing.

Key Advantages of CNC Machining in the Medical Field

There’s a reason CNC machining isn’t just used in labs and factories—it’s trusted in operating rooms, ERs, and diagnostic centers around the world. Let’s break down the specific advantages that make this method a superstar in the medical space.

✅ Precision That Saves Lives

When a surgeon uses a clamp or installs a hip implant, there’s zero room for error. CNC machining offers extreme precision—often beyond what the human eye can even detect. That level of detail can be the difference between a successful procedure and a costly mistake.

✅ Versatility in Designs

Need a tool with tiny grooves? Or an implant with intricate threads and curves? CNC can handle complex geometries with no sweat. Designers and engineers can get creative and still meet functional requirements.

✅ Speed Without Sacrificing Quality

Even under tight deadlines, CNC machining delivers. It’s fast, especially for short runs and prototypes, but doesn’t compromise on quality. That speed-to-market matters when new tools or devices are needed urgently—like during a pandemic or medical supply shortage.

✅ Supports Customization

No two patients are the same. With CNC machining, creating custom medical parts is quick and efficient. Think of a patient-specific prosthetic limb or a dental implant tailored to an individual’s jaw structure. CNC makes it happen—on demand.

✅ Clean and Sterile Production

CNC machines operate in controlled environments, and the parts they make are easy to clean or sterilize. That’s vital when you’re manufacturing something that’s going inside the human body or being used in surgery.

In a nutshell, CNC machining isn’t just meeting the needs of the medical industry—it’s redefining what’s possible. Its speed, flexibility, and ability to meet ultra-high standards make it the go-to method for forward-thinking healthcare manufacturers.

Top Applications of CNC Machined Parts in Healthcare

CNC machining might sound like it’s just for tech nerds and factory floors, but it’s actually playing a huge role in saving lives. Here’s where CNC-machined components are used in the medical world:

🛠 Surgical Tools

Scalpels, clamps, scissors, retractors—these must be ultra-sharp, durable, and perfectly shaped. CNC machining ensures these tools are not only precisely made, but also reliable enough to be sterilized and reused repeatedly.

🦾 Implants & Prosthetics

Whether it’s a titanium hip replacement or a custom knee joint, CNC machining allows implants to be made with exact dimensions tailored to each patient’s anatomy. That’s critical for comfort and long-term success.

🧬 Diagnostic Devices

Think CT scanners, MRIs, and X-ray machines. These aren’t just tech-heavy—they include tons of tiny, high-precision components like brackets, holders, and electronic housings—all often CNC-machined for accuracy.

🩻 Medical Electronics

CNC machining helps produce the enclosures and frames for devices like ventilators, infusion pumps, and wearable monitors. They may not be as flashy as the tools inside, but their structural integrity is vital.

🧰 Lab Equipment

From blood analyzers to centrifuge parts, lab gear often includes plastic and metal parts that demand tight tolerances and perfect alignment—another CNC specialty.

🦷 Dental Tools & Implants

CNC machines also mill out dental crowns, bridges, and orthodontic tools, all custom-fit to individual patients. Talk about precision!

Across every corner of healthcare, CNC machining helps make parts that are strong, safe, and reliable. From the OR to the lab bench, its fingerprint is everywhere.

Common Materials Used in Medical CNC Machining

One of the best things about CNC machining? It plays well with almost any material—especially the ones that matter most in medicine. From life-saving implants to critical surgical tools, selecting the right material is just as important as the machining process itself. Let’s dive into some of the most popular materials used in medical CNC machining and why they matter.

🧪 Stainless Steel

This one’s a classic. Stainless steel is strong, corrosion-resistant, and super hygienic. It’s used in everything from surgical scissors to orthopedic screws because it can be sterilized repeatedly without breaking down. Plus, it has the kind of toughness you want in a material that literally saves lives.

🦾 Titanium

Titanium is a total powerhouse in the medical world. It’s lightweight, super strong, and incredibly biocompatible—meaning the human body won’t reject it. That makes it perfect for implants like hip joints, bone plates, and dental posts. CNC machining helps shape titanium with pinpoint accuracy, even though it’s notoriously tough to work with.

🧯 Aluminum

Aluminum isn’t typically used inside the body, but it’s everywhere in support equipment—like IV poles, wheelchairs, and housing for diagnostic machines. It’s lightweight, easy to machine, and resistant to corrosion, especially when anodized.

🔬 Medical-Grade Plastics

Let’s not forget about plastics. High-performance thermoplastics like PEEK, Delrin, and PTFE (Teflon) are becoming stars in the medical space. They’re great for one-time-use parts, sterilizable tools, or components that need flexibility and insulation.

- PEEK is strong, chemical-resistant, and even X-ray transparent.

- Delrin is rigid and stable, ideal for instruments.

- Teflon holds up under heat and doesn’t react with body fluids.

In short, whether you’re designing a surgical scalpel or a hip implant, there’s a CNC-compatible material out there that fits the job perfectly. The key is knowing what properties matter most—biocompatibility, strength, flexibility—and letting CNC do the rest.

How to Choose the Right Material for Medical Machining

When it comes to medical CNC machining, picking the right material is like choosing the right partner for a complex surgery—you need reliability, compatibility, and performance. But how do you know which material is right for your specific application? Let’s break it down in a simple, real-world way.

✅ Biocompatibility Matters Most

If your part is going inside the human body—even temporarily—you need a material that won’t cause a reaction. That means no toxicity, no inflammation, no rejection. Titanium, stainless steel, and PEEK are top picks for implants and internal devices.

✅ Can It Handle Sterilization?

Medical parts are often exposed to steam, chemicals, and high heat during sterilization. If your material can’t handle repeated cleaning cycles, it’s not going to work in the field. Stainless steel and PTFE are all-stars here—they stay strong even after dozens of autoclave sessions.

✅ Will It Be Used Long-Term or Short-Term?

Short-term parts, like surgical instruments or tubes, don’t need the same durability as implants that will stay in the body for years. That means you can sometimes use more affordable or easier-to-machine materials for temporary use.

✅ Does It Need Strength or Flexibility?

Some components need to be rock-solid, like joint replacements or bone screws. Others, like tubing connectors or wearable monitors, benefit from a bit of give. Choose materials that match the mechanical requirements of your part.

✅ Environmental Resistance

Will the part be exposed to radiation, chemicals, or bodily fluids? If so, make sure your material is corrosion-resistant and stable over time.

Choosing the right material isn’t just about engineering—it’s about thinking like a doctor, a patient, and a product designer all at once. When in doubt? Partner with a CNC shop that knows medical materials inside and out.

Design Tips for CNC Machined Medical Components

Designing medical components isn’t just about creativity—it’s about functionality, safety, and performance. When it comes to CNC machining, even small changes in design can make a big difference in cost, manufacturability, and final quality. Here are some pro-level tips to keep your parts practical and production-ready.

✏️ Keep It Simple, Always

Complex designs are cool—but not when they drive up costs or increase machining time. Avoid unnecessary angles, sharp corners, or overly thin walls. Rounded edges and simple geometries are easier to machine and often stronger.

📏 Design for Tight Tolerances (But Only Where Needed)

Don’t ask for micrometer-level tolerances on every feature unless it’s essential. Over-specifying tolerances can drive up cost and slow production. Focus on tight tolerances only where they’re needed—like mating surfaces or implant contact points.

🔄 Make Maintenance Easy

Design parts so they can be easily assembled, cleaned, or maintained. Think about how a surgeon or nurse will handle this tool. Can it be sterilized easily? Taken apart and reassembled without special tools?

🎨 Use Colors with Caution

In medical environments, color can help with identification and sorting, but be careful. Not all dyes or coatings are compatible with sterilization or biocompatibility. Use color where helpful—but check its impact on material performance.

🧩 Minimize Assembly

If you can machine a part as a single piece instead of multiple assemblies, you’ll reduce potential failure points. That’s a big win in medical devices, where reliability is everything.

With these design strategies, you’re not just making parts—you’re creating medical solutions that are safe, effective, and production-friendly. A little forethought in the design stage goes a long way in the OR.

Key Standards & Certifications for Medical Machining

Let’s talk about trust. In the medical industry, it’s not enough to just say your parts are high-quality—you need the certifications to prove it. Here are the key industry standards that any medical CNC machining operation should meet, and why they matter.

🏥 ISO 13485 – The Medical Standard

This is the gold standard for quality management systems in the medical device industry. If your machining partner is ISO 13485 certified, you know they’ve passed rigorous quality checks specific to healthcare. It covers everything from design to delivery.

🛠 ISO 9001 – General Quality Certification

While not medical-specific, ISO 9001 certification proves that a company has a solid quality management system. It’s a good baseline, especially when combined with ISO 13485.

🔬 FDA & CE Compliance

If you’re planning to market your devices in the U.S. or Europe, they must meet FDA or CE regulations. That means every part of the supply chain—including CNC machining—must comply with strict traceability, documentation, and safety protocols.

🔧 Material Certifications

Reputable machine shops will also provide certifications for every material used. This ensures the materials are medical-grade and meet regulatory requirements.

✅ Why It All Matters

Certified manufacturers follow strict documentation, cleanroom practices, inspection protocols, and traceability. This protects you from product recalls, safety issues, and legal risks.

Bottom line? Don’t settle for uncertified suppliers. The risks are too high. Always ask about certifications—and don’t be afraid to audit their process if your components are high-risk.

Challenges in Medical CNC Machining (and Smart Fixes)

Let’s be real—CNC machining for the medical field isn’t always easy. Between complex designs, tough materials, and ultra-tight tolerances, there are plenty of challenges. But don’t worry—we’ve also got solutions.

❗ Challenge 1: Tight Tolerances

Medical parts often need to be accurate to within microns. That’s a challenge when working with tiny tools and hard materials.

✔ Solution: Use high-precision machines and diamond-coated tools. Also, implement quality control at every stage—not just at the end.

❗ Challenge 2: Hard-to-Machine Materials

Titanium and PEEK are popular, but they’re tough to cut cleanly.

✔ Solution: Use proper feeds, speeds, and coolants. Also, partner with machinists who have experience in medical-grade materials.

❗ Challenge 3: Regulatory Compliance

You can’t just machine a part and ship it. You need full traceability, material certificates, and clean manufacturing practices.

✔ Solution: Work with ISO 13485 certified shops. Look for ones that offer documented inspection protocols and cleanroom capabilities.

❗ Challenge 4: Fast Turnaround Requirements

Hospitals can’t wait weeks for custom parts or replacement implants.

✔ Solution: CNC machining is already fast—but for emergencies, choose shops that offer rapid prototyping and in-house tool design.

❗ Challenge 5: Sterilization Compatibility

Some materials can’t handle heat or chemicals used in sterilization.

✔ Solution: Choose sterilization-compatible materials like stainless steel, titanium, PTFE, or medical-grade nylon.

The bottom line? These challenges are real, but with the right equipment, experience, and processes, they’re 100% manageable. That’s why working with the right partner matters more than ever.

Tips for Working with a CNC Machining Partner

Looking for a supplier to handle your medical CNC parts? Not all machine shops are created equal. When you’re building something that could end up in an operating room or inside a human body, quality isn’t optional—it’s non-negotiable. Here’s how to choose wisely.

👨⚕️ Ask for Medical Experience

Your supplier should have experience with medical-grade materials and part types. Have they worked with titanium, PEEK, or stainless steel? Can they show you examples of previous surgical or implant components?

📋 Check Certifications

ISO 13485 is a must. ISO 9001 is a great bonus. If they’re not certified, they’re not ready for your project.

🔍 Look for In-House Inspection

High-precision parts require in-process quality control. The shop should offer CMM (Coordinate Measuring Machine) reports, visual inspections, and surface roughness testing.

🛠️ Ask About Equipment

Do they have multi-axis CNC machines, Swiss-style lathes, or grinding machines? The more capabilities they have, the more flexible they’ll be.

💬 Communication Is Key

A good machining partner isn’t just a vendor—they’re a team member. Look for clear, consistent communication, fast quotes, and design feedback that helps you reduce costs without sacrificing quality.

Choosing the right machining partner isn’t just about getting parts. It’s about finding someone who understands the life-or-death nature of medical applications—and treats every component with that level of care.

Post-Machining Processes for Medical Components

Making the part is just the beginning. For most medical components, there are several steps that happen after machining to get them ready for use. These extra touches can improve safety, performance, and appearance.

✨ Polishing

Many surgical tools and implants are polished until they shine like mirrors. This isn’t just about looks—it helps prevent corrosion, makes cleaning easier, and improves durability.

🧼 Passivation

This chemical process removes contaminants (like free iron) from stainless steel surfaces. It helps improve corrosion resistance, especially for parts that go through repeated sterilization.

🌡️ Sterilization Preparation

Some CNC shops offer packaging or cleaning processes that make parts ready for immediate sterilization—whether by steam, radiation, or chemicals.

🎯 Laser Marking

Need to add a serial number, company logo, or calibration mark? Laser engraving is precise, permanent, and safe for medical use.

⚙️ Coating or Plating

Certain parts might get coated with ceramic, PVD, or antimicrobial finishes. These can reduce friction, improve bio-compatibility, or make parts easier to use.

Post-processing isn’t just a “nice to have”—for many medical applications, it’s a must. These finishing touches can mean the difference between a good part and a great one.

Future of CNC Machining in the Medical Field

As tech keeps advancing, CNC machining is only getting more powerful—and more essential—for healthcare.

🔬 Micromachining

Need a component the size of a grain of rice? CNC machines can now handle micro tools and deliver parts used in eye surgeries, hearing aids, and advanced diagnostics.

🧠 AI-Powered Toolpath Optimization

CNC software is getting smarter. With AI, machines can optimize tool movement in real-time, reducing wear, improving finish, and saving materials.

🖨️ CNC + 3D Printing Hybrid Machines

Some companies are combining subtractive (CNC) and additive (3D printing) processes in one setup. Perfect for custom implants or one-off tools.

🧬 Biomaterials

We’re moving beyond titanium. New biocompatible polymers and composites are opening up new frontiers for lighter, more flexible, and longer-lasting medical devices.

🌍 More Sustainable CNC Practices

With a push for eco-friendly manufacturing, CNC shops are recycling chips, using water-based coolants, and reducing energy waste.

The future? Faster production, fewer errors, more custom options, and a better patient experience. CNC is no longer just a machining method—it’s part of the healing process.

Conclusion

Medical CNC machining isn’t just about cutting metal—it’s about saving lives, improving care, and advancing technology. From orthopedic implants to precision surgical tools, CNC machining delivers exact, clean, and safe components for a rapidly growing healthcare industry.

Whether you’re a medical startup or an established equipment manufacturer, CNC machining can offer you:

💡 Unmatched precision

⚙️ Flexibility in design and material

⏱️ Fast production times

🏥 Reliable, patient-safe results

The key? Partnering with a certified, experienced CNC manufacturer who understands your needs, your challenges, and your mission.

FAQs

1. What are the best materials for CNC machining medical parts?

Titanium, PEEK, stainless steel, and Delrin are popular due to their biocompatibility and resistance to sterilization methods.

2. Can CNC machines make implants?

Yes! CNC machining is widely used to make custom and standard implants like hip joints, dental screws, and bone plates.

3. How accurate is medical CNC machining?

Very accurate—CNC machining can achieve tolerances as tight as ±0.001 mm, ideal for precision-critical parts.

4. What certifications should I look for in a medical CNC supplier?

ISO 13485 (medical-grade manufacturing), ISO 9001 (general quality), and FDA compliance if operating in the U.S.

5. Can CNC machining be used for prototype and production?

Absolutely. CNC machining is perfect for both one-off prototypes and full production runs, with no need for new tooling between versions.