Zinc is a metal with various industrial applications. One key property is its melting point. The melting point of zinc is 419.5°C (787.1°F). This is relatively low compared to many other metals.

Zinc melts at this temperature under normal atmospheric pressure. This allows it to be easily melted and cast into shapes. Moreover, it is often used in galvanizing steel and die-casting processes. The low melting point makes zinc a versatile material for such processes. In this, we will explore various aspects of Zinc in terms of properties, industrial uses, and machining techniques.

What Is Zinc?

Zinc Properties

Zinc is a metallic element with the chemical symbol Zn and atomic number 30. It is commonly used in alloys and galvanization and is an essential nutrient in both plants and animals.

Comparison of Zinc’s Melting Point with Other Metals

In comparison to other metals, zinc has a moderate melting point. For example, aluminum has a melting point of 660°C, which is far higher than zinc. Moreover, lead has a comparatively low melting point of 327°C. The melting phase also supports the use of zinc in alloys.

Moreover, certain zinc alloys have comparatively lower melting points than their base metal. For instance, zinc-aluminum alloy is quite popular. These types of alloys are easier to shape at relatively low temperatures. Therefore, they are cheaper to form into products.

In addition, the melting point of zinc existing in the form of alloys changes with additions of other elements. It is a composition-sensitive system and minute variations in the composition can influence heat response.

Properties of Zinc:

| Property | Value |

| Chemical Symbol | Zn |

| Atomic Number | 30 |

| Atomic Mass | 65.38 g/mol |

| Density | 7.14 g/cm³ |

| Melting Point | 419.5°C (787.1°F) |

| Boiling Point | 907°C (1665°F) |

| Thermal Conductivity | 116 W/m·K |

| Electrical Conductivity | 1.69 × 10⁶ S/m |

| Hardness | 2.5 (Mohs scale) |

| Crystal Structure | Hexagonal close-packed (hcp) |

| Young’s Modulus | 108 GPa |

| Tensile Strength | 100 MPa |

| Corrosion Resistance | High (especially in alkaline and neutral environments) |

| Magnetic Properties | Diamagnetic |

The table above covers the key technical properties of zinc, including its chemical and physical characteristics.

Factors Influencing Zinc Melting Temperature

Here are the common factors influencing zinc’s melting temperature.

1. Purity of Zinc

The melting point of zinc varies according to the metal quality. The higher the quality of zinc, the higher the melting time it takes. However, a slight presence of impurities in zinc can either raise or lower the melting temperature. For example, the use of iron or lead lowers the melting point marginally.

2. Alloying Elements

The reaction of zinc with other metals affects the melting point of a certain type of alloy. The most commonly used alloys are Zinc aluminum or Zinc copper alloys and their melting points are comparatively lower than pure Zinc. The presence of other elements introduces breaks within the crystal frame. Therefore, the metal can be melted at a high temperature without much difficulty.

3. Atmospheric Pressure

Another characteristic of the materials is the pressure which affects the melting temperature. For instance, zinc, at higher altitudes or reduced pressures, the melting point diminishes. Because pressure and the phase transition of metals are correlated. However, the increment is small when the environment is under normal working conditions.

Melting Point Ranges of Common Zinc Alloys

| Zinc Alloy | Composition | Melting Point Range |

| Zinc-Aluminum (ZA) | 85-95% Zinc, 5-15% Aluminum | 380°C – 390°C (716°F – 734°F) |

| Zinc-Copper (ZC) | 90-97% Zinc, 2-5% Copper | 400°C – 420°C (752°F – 788°F) |

| Zinc-Lead (ZL) | 90-95% Zinc, 5-10% Lead | 330°C – 380°C (626°F – 716°F) |

| Zinc-Fe (Zinc-Iron) | Zinc with small amounts of Iron | 400°C – 420°C (752°F – 788°F) |

| Zinc-Tin (ZT) | 90-99% Zinc, 1-10% Tin | 370°C – 410°C (698°F – 770°F) |

| Zinc-Aluminum (ZA-27) | 73% Zinc, 27% Aluminum | 365°C – 400°C (689°F – 752°F) |

Machining Techniques for Zinc

Zinc is a versatile material that can be machined by various machining techniques. Here are some common machining methods for zinc:

1. Zinc CNC Turning

Rotational machining is a common technique for transforming zinc into valuable parts or products. The material is turned while the cutting tool removes materials to give it a cylindrical shape. Due to the relatively low hardness of zinc, it can be turned by high-speed steel or carbide tools.

2. Zinc CNC Milling

Milling involves a cutter applying a rotary motion to carve zinc stock material. It is mostly utilized in making plain surfaces, slots, and other intricate features. In most cases, carbide or high-speed steel tools are used on zinc, since, it is relatively soft.

3. Zinc CNC Drilling

Zinc alloys usually require holes to be drilled. Hence, CNC drilling is common with such zinc alloys. For hot forging zinc, special carbide-tipped or cobalt drills are employed during drilling to minimize heat generation and the resultant brittleness.

4. Zinc CNC Grinding

Zinc Finished Parts

Grinding is applied when a high surface finish is needed. Moreover, if you need to remove a small amount of material. When working on zinc, a fine-cutting wheel is used to generate excessive heat which alters the zinc properties.

5. Tapping

Hitting or Tapping are used to make internal threads in zinc alloys. As for the toppings, because zinc is comparatively soft, standard tappings may be used. Care must be taken not to cause the material to crack or tear.

Applications of Zinc In Various Industries

Here are 5 key applications of zinc:

1. Galvanization

Zinc most benefits iron and steel by protecting them from rust and corrosion through galvanizing. Through galvanization, the surface of metals like iron, steel, and automobiles are protected making structures such as bridges, pipelines, and automobiles last longer.

2. Die Casting

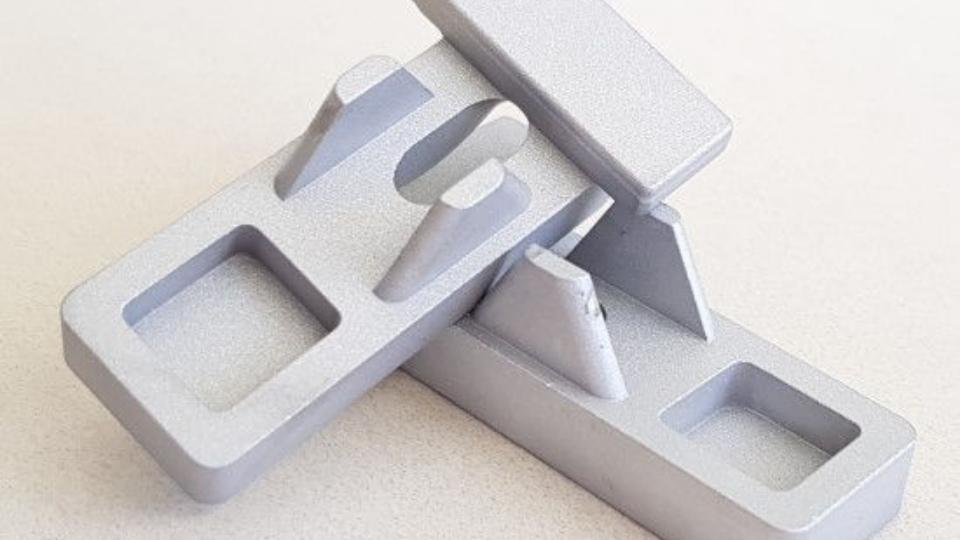

Zinc Die Cast Product

Zinc alloys are preferred in die casting mostly. Moreover, the process helps create automotive, electronics, and hardware components since the parts developed will be tough.

3. Battery Manufacturing

Zinc is a strategic component used in the formulation of batteries especially alkaline and zinc-carbon batteries. Because, it is malleable and can be used to store energy while providing efficient energy for devices from home appliances, to vehicles.

4. Brass Production

Zinc is an active ingredient in the manufacture of brass, a metal composite of copper and zinc. It can be utilized for plumbing purposes, as well as in the production of musical instruments and ornamental products.

5. Agriculture

Zinc is a micronutrient in fertilizers and has the duty of contributing to plant growth. It increases the yield, stands against diseases, and helps in photosynthetic processes. In addition, zinc can also be used as a supplement in animal feeds, and diets.

Summary

The article summary in a frame:

- Zinc has a low melting point of 419.5°C, making it ideal for various industrial processes.

- It is commonly used in galvanization, die casting, and battery manufacturing.

- Zinc alloys, such as zinc-aluminum and zinc-copper, have different melting point ranges.

- Machining techniques for zinc include turning, milling, drilling, grinding, and tapping.

- Zinc plays a crucial role in industries like automotive, construction, and agriculture.

FAQ’s About Melting Point of Zinc

Q1. How does atmospheric pressure affect the melting point of zinc?

At higher altitudes or reduced pressure, the melting point of zinc can decrease slightly.

Q2. What are the benefits of using zinc in die casting?

Zinc’s low melting point allows for efficient, cost-effective die casting, producing precise and durable components.

Q3. Why is zinc commonly used for galvanization?

Zinc protects steel and iron from corrosion by forming a protective coating, making it ideal for outdoor structures and vehicles.

Q4. How does zinc’s hardness compare to other metals?

Zinc has a Mohs hardness of 2.5, making it relatively soft compared to many other metals.

Q5. Can zinc be used in high-temperature applications?

Zinc is not ideal for high-temperature applications due to its relatively low melting point, but it is well-suited for processes that occur at moderate temperatures.

4 thoughts on “Melting Point of Zinc, Properties, Uses & Facts”