Welcome to Tops Precision: Your Go-To for Metal Machining Excellence

Tops Precision serves many different businesses across various industries through its role as a custom CNC machining service provider. Your required specifications determine the manufacturing quality of our parts, regardless of production size, starting from prototypes to large-scale productions.

Our CNC technology-operating team uses different metal materials to make accurate parts that precisely fulfill your specifications. The company provides high-end metal materials from aluminum to titanium that support various sectors such as automotive and medical and aerospace and others.

Send Your Inquiry Today

Why Our Customers Trust Us for Metal Machining?

Our production process at Tops Precision implements solution development for unique customer requirements. Multiple driving forces keep our clients dedicated to our company, according to the evidence below.

Precision at Its Best

Our CNC machines operate at the facility by producing components that fulfill ±0.005 mm tolerance dimensions. Essential applications need precise measurements for medical devices, and they also apply to aerospace and automotive parts.

Fast Turnaround Time

The company fully recognizes your instant need for project solutions. Our main service consists of prototyping and rapid turnaround because it allows multiple part manufacturing in three days. The delivery service provided by our company accommodates both short-run small-scale deliveries and large-scale manufacturing orders according to your production schedule requirements.

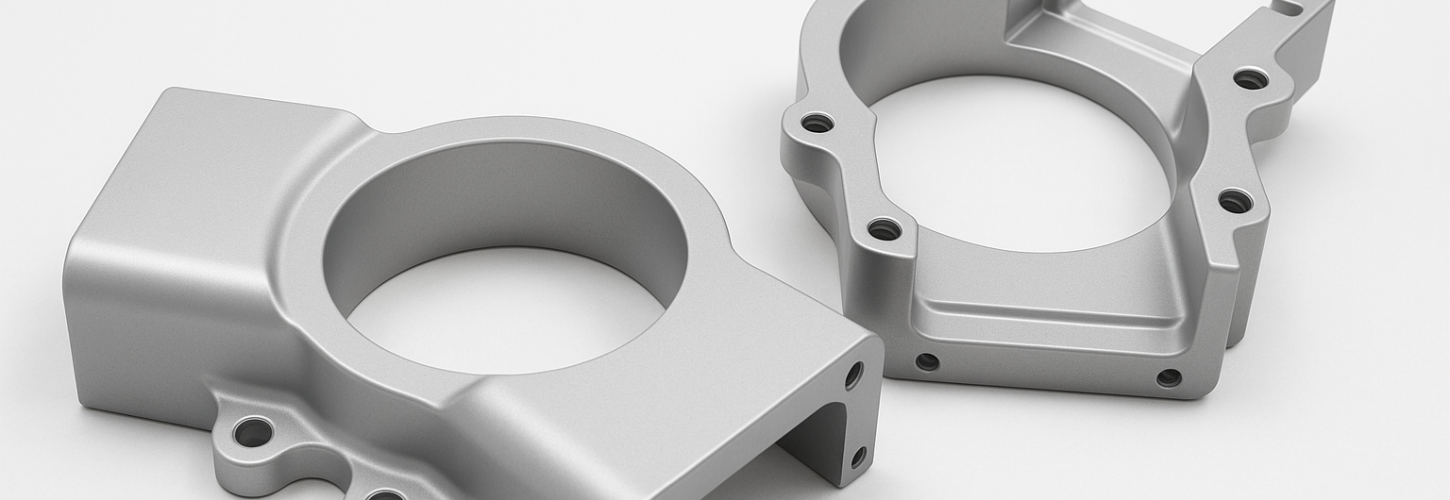

Customization to Fit Your Needs

Versaterm implements customized solutions for every project that the team handles independently. The team of experts works directly on developing conceptual designs from your special design requirements and finish needs, together with custom-shaped part details.

High-Quality Materials

Quality starts with the material. Customers receive access to metal products which combine stainless steel resistance to corrosion with aluminum weight reduction attributes through the company. Any chosen material from our selection matches your project requirements for sustainable part operation.

Support Every Step of the Way

The team at the company supports your project from the start of development until its complete completion without interruptions. Our team provides continuous support for your material selection along with design changes from the beginning to the end of your smooth developmental process. Clients can obtain free consultation in addition to round-the-clock customer support from the company in order to achieve their optimal results.

Send Your Inquiry Today

Our Metal Machining Process: From Concept to Completion

Tops Precision uses an exact methodological approach that establishes precise solutions for our customers in every manufacturing project. Here’s how we work:

Step 1: Understanding Your Needs

All project requirements receive clarification that entails selecting materials and specifying design specifications and precision standards, along with surface quality expectations. A collaborative process enables engineers from our team to create an official plan for your part structure with your direct involvement as their client.

Step 2: Design and CAD Modeling

Our team begins CAD modeling once it captures all essential specifications. The visual design and problem detection along with optimal manufacturing setup become possible because of these models.

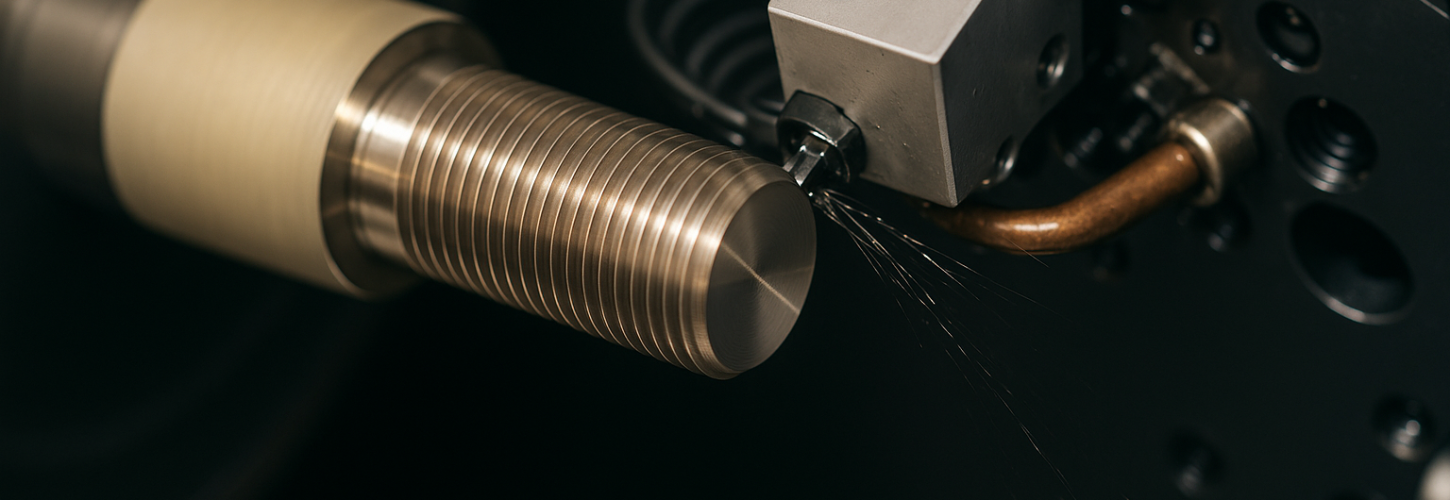

Step 3: CNC Machining

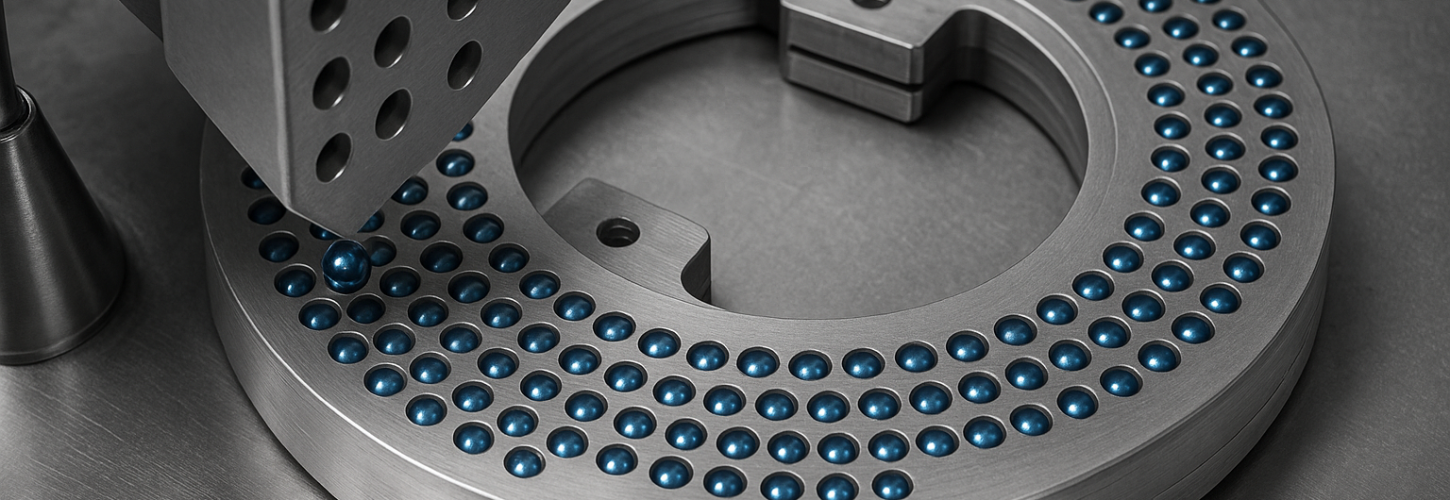

The contemporary CNC machines at our facility carry out the production of your designed products. Our equipment provides exact precision-level treatment to each manufacturing process, including milling, followed by turning after laser cutting, before drilling.

Step 4: Quality Control

A complete quality control examination takes place before the release of your items when they meet your precise specifications. The testing process includes measuring dimensions and inspecting surface finish to confirm accurate results.

Step 5: Finishing Touches

Our business delivers several finishing choices which encompass both polishing and anodizing and sandblasting with powder coating to improve part quality. The applied finishing processes defend parts from damage while optimizing their operational capabilities under specific conditions.

Send Your Inquiry Today

Choose from a Variety of Premium Metal Materials

The material you choose is crucial to the performance of your parts. At Tops Precision, we offer a wide range of metals, each carefully selected for its unique properties. Below is an overview of the most popular metals we work with:

Metal Type | Key Features | Ideal Applications | Benefits | Parts Made |

Lightweight, corrosion-resistant, good weldability. | Automotive parts, aerospace components, and structural frames. | Great strength-to-weight ratio, easy to machine. | ||

Strong, corrosion-resistant, easy to clean, durable. | Medical devices, food processing, and industrial machinery. | Long-lasting and resistant to corrosion and rust. | ||

Enhanced resistance to corrosion, especially in harsh conditions. | Marine equipment, chemical processing, and surgical tools. | Superior resistance to saltwater and chemicals. | ||

Malleable, excellent conductivity, corrosion-resistant. | Electrical components, plumbing fittings, and valves. | Great machinability and natural corrosion resistance. | ||

Extremely strong, lightweight, corrosion-resistant. | Aerospace, high-performance sports equipment, and medical implants. | High strength and lightweight, ideal for extreme conditions. | ||

Strong, versatile, and affordable. | Industrial machinery, automotive components, and structural parts. | Cost-effective, strong, and easy to weld. | ||

Excellent conductivity, corrosion-resistant. | Electrical connectors, heat exchangers, and plumbing. | Excellent conductivity, non-corrosive properties. | ||

High hardness, wear-resistant. | Molds, cutting tools, dies, and industrial equipment. | Ideal for tools that require wear resistance and toughness. | ||

Bronze | Corrosion-resistant, strong, non-sparking. | Bearings, bushings, marine parts. | Excellent wear resistance, ideal for friction-based applications. |  |

Send Your Inquiry Today

Industries We Serve

Multiple sectors of industry professionals endorse the trusted metal machining services. Here’s how we help:

Aircraft: Our company manufactures aircraft components in addition to aerospace engine parts and spacecraft equipment that operate under rough environmental conditions.

Automotive: We supply precise parts for engine assembly alongside gears and chassis components to the automotive industry.

Medical: Our company offers surgical tools and medical implants, and medical devices to the medical sector and these products need to be both precise and completely sterile.

Mechanical: During manufacturing and production operations, industrial equipment personnel design both mechanical components and machine parts, together with gears.

Energy: Producing components for the oil & gas industry, as well as wind turbines and hydroelectric equipment.

Why Work with Top Precision?

- Our company guarantees parts fabrication with exact measurements that meet your precise requirements for small dimensional variances.

- You can obtain your custom metal components rapidly through both fast prototyping and short lead times.

- Our team of experienced engineers assists customers through all production phases, starting from design to final delivery.

- Our company strictly follows ISO-certified quality standards for every project we undertake.

- Quality machining services are available at affordable prices without compromise to their standard. The company delivers budget-friendly solutions that maintain superior quality throughout all stages of production.

Ready to Get Started?

You should never admit anything inferior to what you truly seek. Customers who require high-quality precise reliable metal parts should choose Tops Precision for their requirements. Our team is available right now to provide you with free quotes and project consultations and quick prototype development.