3-mecanizado del eje se destaca como un proceso fundamental que ha remodelado la fabricación de precisión. Ya sea en aeroespacial, automotor, médico, o industrias electrónicas, Este método de mecanizado juega un papel vital en la creación de partes complejas con alta precisión..

Pero, ¿qué es exactamente el mecanizado de 3 ejes?? ¿Cómo funciona?? ¿Cuáles son sus ventajas y limitaciones en comparación con las tecnologías más avanzadas como 5-mecanizado del eje? En esta guía completa, Exploraremos todo lo que necesita saber sobre el mecanizado de 3 ejes, de sus principios básicos a sus aplicaciones del mundo real.

¿Qué es el mecanizado de 3 ejes??

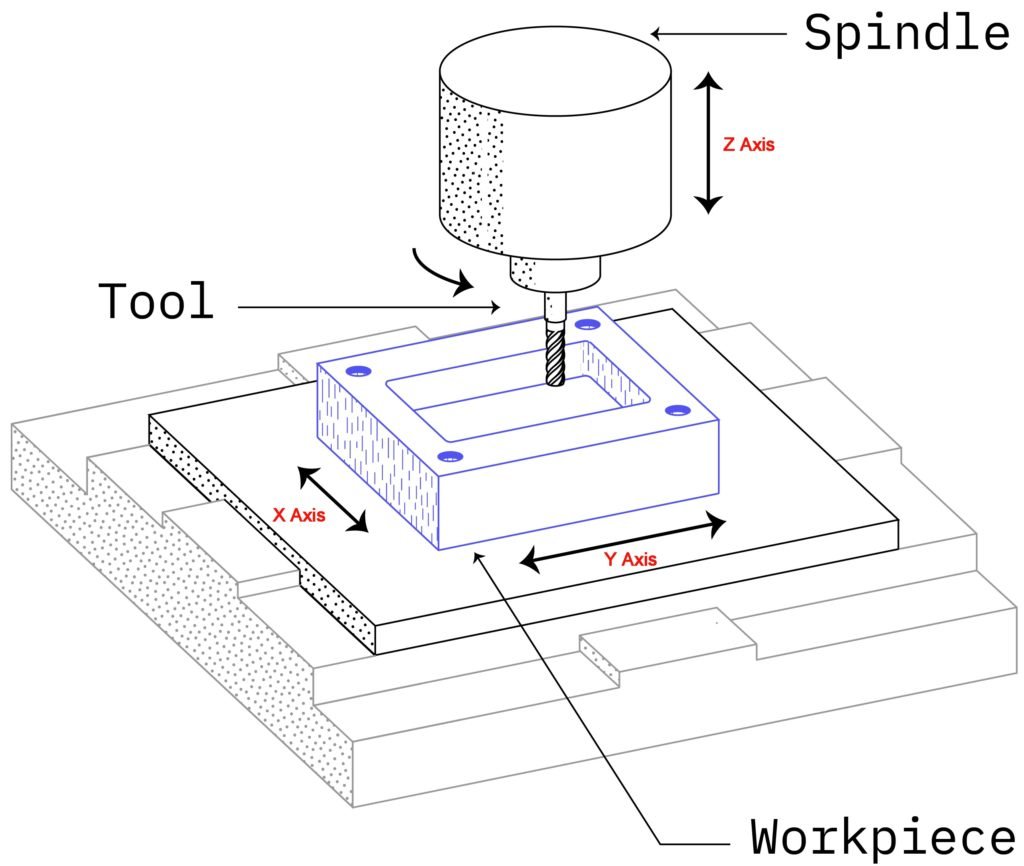

En su núcleo, 3-mecanizado del eje es un proceso de fabricación donde una herramienta de corte se mueve a lo largo de tres ejes perpendiculares: x (izquierda y derecha), Y (hacia adelante y hacia atrás), y Z (hacia arriba y hacia abajo)—Po dar forma a un material. Este método se usa comúnmente en CNC (Control numérico por computadora) mecanizado, donde una computadora automatiza el movimiento de la herramienta de corte para garantizar la precisión.

Características clave del mecanizado de 3 ejes

✔ Movimiento controlado - La herramienta se mueve en tres direcciones para la eliminación de material eficiente.

✔ Corte de precisión - Ideal para crear componentes detallados y precisos.

✔ Automatización con CNC - Reduce el error humano y aumenta la velocidad de producción.

Cómo el mecanizado de 3 ejes difiere de otros métodos

- En comparación con mecanizado manual, 3-El mecanizado del eje permite una mayor precisión y repetibilidad.

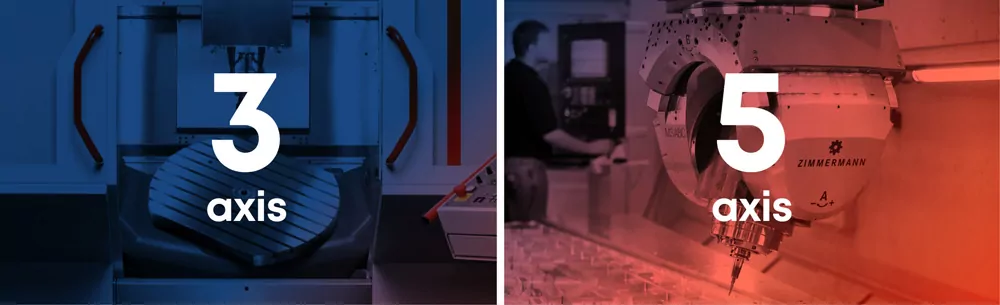

- A diferencia de 5-mecanizado del eje, no gira alrededor de ángulos adicionales, haciéndolo un poco menos versátil pero más rentable.

- Mecanizado de múltiples eje(como 4 ejes y 5 ejes) proporciona flexibilidad adicional para geometrías complejas, Pero a un costo más alto.

3-El mecanizado del eje sigue siendo una de las técnicas más utilizadas en la fabricación debido a su equilibrio de asequibilidad y precisión.

Cómo funciona el mecanizado de 3 ejes

El proceso de mecanizado de 3 ejes consta de múltiples pasos, asegurando un flujo de trabajo suave de materia prima hasta producto terminado.

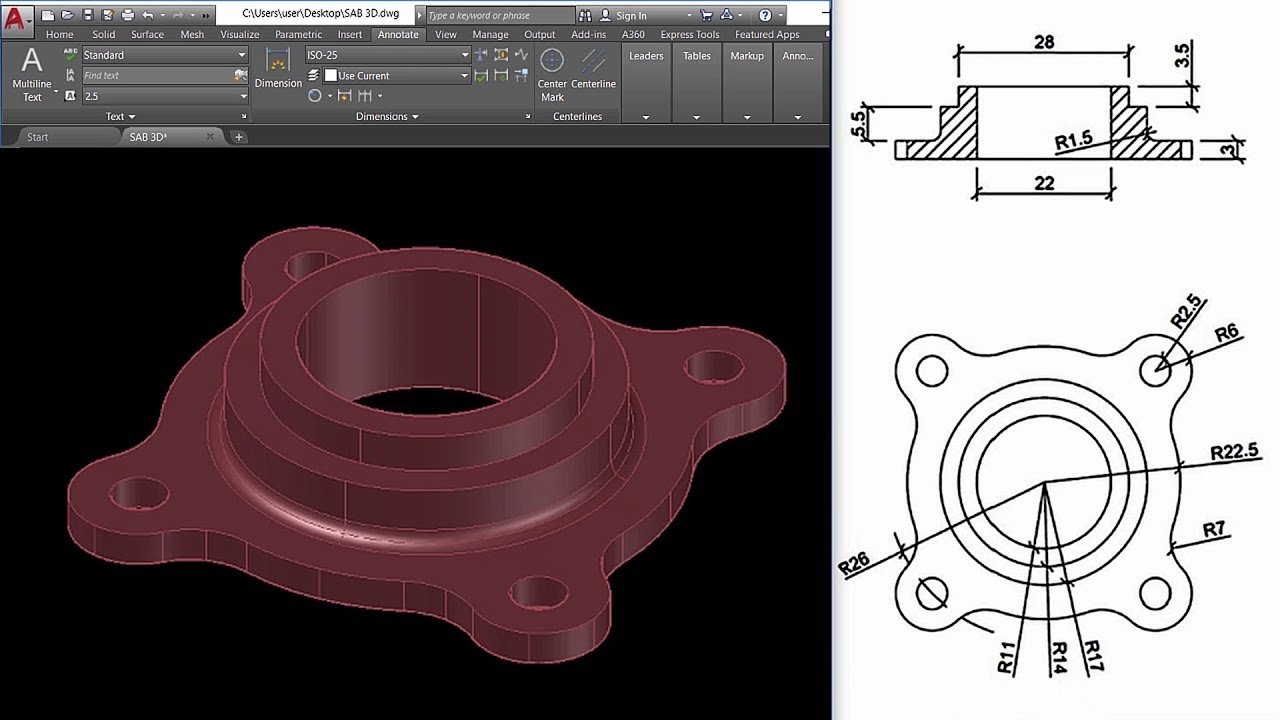

Paso 1: Programación de la máquina CNC

Antes de que comience el mecanizado, a CANALLA (Diseño asistido por computadora) modelo de la parte se crea. Este plan digital se convierte en LEVA (Fabricación asistida por computadora) instrucciones, guiando la máquina CNC.

Paso 2: Asegurando la pieza de trabajo

El material (metal, plástico, madera, etc.) está firmemente sujetado para evitar el movimiento durante el mecanizado.

Paso 3: Cortar y dar forma al material

Uso de herramientas de corte giratorias como ejercicios, molinos, o fábricas finales, La máquina CNC elimina el exceso de material para lograr la forma deseada.

Paso 4: Control de acabado y calidad

Una vez que el mecanizado está completo, Técnicas de acabado como pulido, lijado, o el revestimiento se aplican para mejorar la calidad de la superficie. La parte final se inspecciona para obtener precisión y consistencia..

Este automatizado, El proceso paso a paso asegura que cada parte cumpla con los estrictos estándares de calidad, Hacer que el mecanizado de 3 ejes sea una opción preferida para la fabricación de precisión.

Tipos de máquinas utilizadas en el mecanizado de 3 ejes 🏭

3-Axis Máquinas de fresado CNC 🏗️ - El caballo de batalla del mecanizado

Mejor para: Corte, organización, y perforar materiales sólidos como el metal, plástico, y madera.

- como funciona:

A Herramienta de corte giratoria se mueve a lo largo del incógnita, Y, y ejes Z Para eliminar el material de una pieza de trabajo estacionaria. La herramienta de corte puede crear superficies planas, tragamonedas, y agujeros, haciéndolo el mas común Tipo de máquina de 3 ejes. - Por qué es genial:

✔ Perfecto para mecanizado general

✔ puede manejar una variedad de materiales(rieles, plástica, composicion).

✔ Alta precisión para piezas industriales y comerciales.

💡 Ejemplo: Si estás mecanicando piezas del motor, soportes de metal, o moldes, Una fresadora de 3 ejes es tu mejor amigo!

3-Centros de mecanizado de Axis CNC ⚙️ - Más características, Más poder

Mejor para: Producción de alto volumen de piezas complejas con múltiples operaciones.

- como funciona:

Similar a un fresadora, pero con más automatización y características avanzadas como cambiadores de herramientas, sistemas de refrigerante, y velocidades de corte más rápidas. Esto lo hace ideal para la producción a gran escala. - Por qué es genial:

✔ reduce la necesidad de intervención manual.

✔ Producción más rápida = Costos más bajos por parte.

✔ puede realizar Operaciones de mecanizado múltiples en una configuración.

💡 Ejemplo: Utilizado en automotor, aeroespacial, e industrias médicas para piezas que requieren precisión y repetibilidad.

3-Axis CNC Tornhes 🌀 - Lo mejor para piezas redondas

Mejor para: Girar las partes cilíndricas como los ejes, tubería, y sujetadores.

- como funciona:

En lugar de una herramienta de corte giratoria, a CNC Lathe gira la pieza de trabajo mientras una herramienta estacionario se mueve a lo largo del Ejes x y z para darle forma. Algunos modelos tienen un tercer eje para molienda o perforación lateral. - Por qué es genial:

✔ Produce perfectamente redondo partes con alta precisión.

✔ más rápido que la molienda para objetos cilíndricos.

✔ puede manejar materiales duros como titanio y acero inoxidable.

💡 Ejemplo: Si estás haciendo pistones de motor, tornillos, o pernos personalizados, Un torno de 3 ejes es el camino a seguir!

3-Enrutadores CNC del eje 🏡 - ideal para madera, Plástico & Espuma

Mejor para: Cortar materiales más suaves como madera, acrílico, y espuma para muebles, señales, y piezas decorativas.

- como funciona:

A broca giratoria de alta velocidad se mueve a lo largo de tres ejes para esculpir, cortar, y materiales de forma. A diferencia de las fresadoras, Los enrutadores CNC están construidos para materiales más ligeros y a menudo tener mesas de vacío para mantener las piezas de trabajo. - Por qué es genial:

✔ Cortes madera, plástico, y espuma con velocidad y precisión.

✔ Genial para fabricación de muebles, señalización, y prototipos.

✔ puede crear diseños intrincados y tallas en 3D.

💡 Ejemplo: Utilizado por fabricantes de gabinetes, firmar a las empresas, y bricolaje para cortar muebles personalizados, paneles decorativos, y grabados artísticos.

3-Axis CNC Máquinas de grabado ✍️ - Para marcas detalladas

Mejor para: Texto grabado, patrones, y diseños intrincados en metal, plástico, y madera.

- como funciona:

Usa un pequeño, herramienta de corte de alta velocidad a grabar o grabar diseños en una superficie. Se puede usar para joyería personalizada, trofeos, placas de identificación, y marca. - Por qué es genial:

✔ Crea finos detalles y marcas precisas.

✔ Perfecto para logotipos, números de serie, y grabado personalizado.

✔ Funciona en metal, plástico, madera, e incluso vidrio.

💡 Ejemplo: Si necesitas grabar un logotipo de la compañía en herramientas de metal o un nombre personalizado en una placa de madera, esta es la máquina para el trabajo!

3-Cortadores de plasma CNC del eje 🔥-El cortador de servicio pesado

Mejor para: Cortar láminas de metal gruesas con velocidad extrema y precisión.

- como funciona:

Usa un antorcha de plasma súper candente para cortar el metal derritiéndolo. A diferencia de las fresadoras, cortadores de plasma No elimine el material-ellos quemarlo - Por qué es genial:

✔ Cortes acero, aluminio, y otros metales gruesos con facilidad.

✔ Mucho más rápido que el aserrado o el cizallamiento tradicional.

✔ Funciona bien para aplicaciones industriales como construcción naval y construcción.

💡 Ejemplo: Utilizado en automotor, fabricación de metal, y construcción industrial Para cortar rápidamente grandes hojas de metal.

¿Qué máquina de 3 ejes es adecuada para ti?? 🤔

| Tipo de máquina | Mejor para | Materiales | Por qué elegirlo? |

| Fresadora CNC | Mecanizado general, piezas planas, agujeros, tragamonedas | Rieles, plástica, composicion | Preciso, versátil, ampliamente utilizado |

| Centro de mecanizado CNC | Producción de alto volumen, partes complejas | Rieles, plástica, composicion | Automatizado, eficiente, multitarea |

| Torno de CNC | Partes cilíndricas (ejes, pernos, anillos) | Rieles (acero, aluminio, titanio) | Alta precisión, rápido para piezas redondas |

| Enrutador CNC | carpintería, muebles, señalización, creación de prototipos | Madera, plástica, espuma | Rápido, Tallado detallado & organización |

| Máquina de grabado CNC | Logotipos, texto, grabados decorativos | Metal, madera, plástico | Detalle, Perfecto para la marca |

| Cortador de plasma CNC | Cortar sábanas de metal gruesas | Acero, aluminio, aleaciones | De servicio pesado, uso industrial |

Aplicaciones de mecanizado de 3 ejes

Debido a su exactitud, eficiencia, y rentabilidad, 3-El mecanizado del eje se usa ampliamente en múltiples industrias.

Industria automotriz 🚗

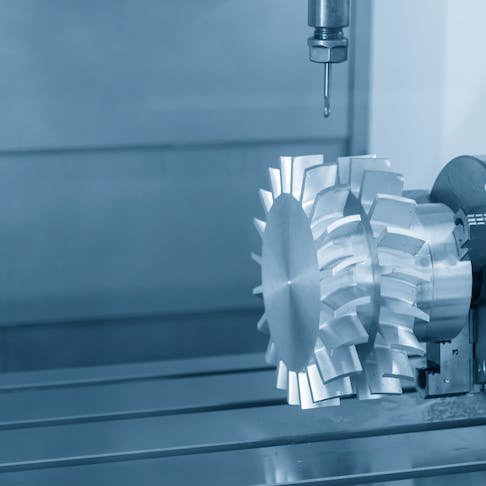

✔ Produce componentes del motor, piezas de transmisión, y engranajes.

✔ Asegura una alta precisión en la fabricación de automóviles.

Industria aeroespacial ✈️

✔ Crea cuchillas de turbina, paneles de instrumentos, y piezas de aeronaves estructurales.

✔ Requiere una precisión extrema para la seguridad y el rendimiento.

Industria médica 🏥

✔ Utilizado para hacer herramientas quirúrgicas, implantes ortopédicos, y prótesis.

✔ Exige precisión para aplicaciones médicas.

Industria electrónica 📱

✔ Produce carcasas, tablas de circuito, y componentes semiconductores.

✔ Asegura la miniaturización de dispositivos de alta tecnología.

Joyas & Industria de grabado 💍

✔ Crea detallado, piezas de joyería de diseño personalizado.

✔ ideal para grabar logotipos, patrones, e inscripciones.

Estas diversas aplicaciones destacan la versatilidad del mecanizado de 3 ejes en la fabricación moderna.

Los beneficios del mecanizado de 3 ejes 🚀

Fácil de usar & Ampliamente disponible 🏭

- Por que importa: 3-El mecanizado del eje es uno de los métodos de mecanizado CNC más comunes, para que no necesite buscar equipos especializados. Muchos talleres de máquinas ya tienen estas máquinas, lo que significa tiempos de respuesta más rápidos y costos más bajos.

- ¿Qué es lo bueno de eso??

✔ Programación simple en comparación con las máquinas de 5 ejes.

✔ Más fácil para los operadores aprender y usar.

✔ No hay necesidad de software ultra complejo.

💡 Ejemplo: Si necesita una placa de metal básica con agujeros o un soporte simple, Una máquina de 3 ejes puede hacerlo rápida y asequible!

Rentable 💰

- Por que importa: 3-Las máquinas CNC del eje son más barato para comprar, correr, y mantener comparado con más avanzado 4- o máquinas de 5 ejes. Esto los convierte en una excelente opción para las empresas que buscan mantener los costos bajos.

- ¿Qué es lo bueno de eso??

✔ Costos más bajos de la máquina significa piezas más baratas para clientes.

✔ Menos tiempo de configuración = producción más rápida y menores costos de mano de obra.

✔ Utiliza herramientas de corte estándar, que son fáciles de reemplazar.

💡 Ejemplo: Si una empresa necesita producir cientos de pequeños, piezas simples, 3-El mecanizado del eje es un asequible y eficiente elección.

Alta precisión & Precisión 🎯

- Por que importa: Aunque las máquinas de 3 ejes son más simples que las máquinas de 5 ejes, Todavía pueden producir extremadamente preciso y preciso

- ¿Qué es lo bueno de eso??

✔ puede lograr tolerancias tan apretadas como ± 0.01 mm.

✔ Asegura la repetibilidad, cada parte sale exactamente lo mismo.

✔ Funciona muy bien para superficies planas, agujeros, y geometrías estándar.

💡 Ejemplo: Si estás haciendo piezas aeroespaciales o médicas, La precisión lo es todo. Una máquina de 3 ejes puede Cortar con precisión precisa Para garantizar un ajuste perfecto!

Tiempo de producción más rápido ⏳

- Por que importa: Porque las máquinas de 3 ejes son fácil de programar y operar, Pueden cortar partes rápidamente sin largos tiempos de configuración.

- ¿Qué es lo bueno de eso??

✔ Menos espera—Paster Cutting = más piezas producidas en menos tiempo.

✔ eficiente para producción a granel de piezas simples.

✔ Perfecto para cumplir con los plazos ajustados.

💡 Ejemplo: Un fabricante haciendo 100 Soportes de metal para una empresa automotriz puede mecanizarlos en un solo dia Usando un CNC de 3 ejes!

Funciona en una amplia gama de materiales 🏗️

- Por que importa: 3-El mecanizado del eje no se limita solo al metal: puede cortar plástica, madera, composicion, y más.

- ¿Qué es lo bueno de eso??

✔ Funciona en acero, aluminio, latón, y titanio.

✔ También puede máquina plásticos como acrílico, policarbonato, y nailon.

✔ Incluso genial para Corte de carpintería y espuma.

💡 Ejemplo: Si eres fresar una parte automotriz de metal o cortar un signo de madera, Una máquina de 3 ejes puede manejar el trabajo!

Ideal para prototipos & Producción de lotes pequeños 🏎️

- Por que importa: Necesito probar un nuevo diseño de producto? 3-El mecanizado del eje es Perfecto para hacer prototipos Antes de comprometerse con la producción a gran escala.

- ¿Qué es lo bueno de eso??

✔ rápido y prototipos de bajo costo.

✔ Diseños fáciles de ajustar y hacer ajustes.

✔ No hay necesidad de costos de configuración costosos.

💡 Ejemplo: Una startup que diseña una nueva caja de reloj inteligente puede Machine algunos prototipos en aluminio antes de decidir el diseño final.

Bajo mantenimiento & Máquinas duraderas 🛠️

- Por que importa: A diferencia de las máquinas de 5 ejes de alta gama, 3-Las máquinas de eje son más fácil de mantener y durar más porque tienen menos partes móviles.

- ¿Qué es lo bueno de eso??

✔ Menos riesgo de falla mecánica.

✔ Bajo costos de reparación En comparación con las máquinas CNC avanzadas.

✔ Las máquinas pueden durar años o incluso décadas con el cuidado adecuado.

💡 Ejemplo: Una máquina de fresado de 3 ejes bien mantenida puede seguir corriendo 10+ años, convirtiéndolo en una gran inversión a largo plazo!

Ideal para piezas simples a moderadamente complejas ⚙️

- Por que importa: No todos los proyectos necesitan una máquina súper avanzada de 5 ejes. Si tu diseño es simple o moderadamente complejo, una máquina de 3 ejes Hace el trabajo de manera eficiente.

- ¿Qué es lo bueno de eso??

✔ Perfecto para piezas planas, agujeros, y formas estándar.

✔ puede crear engranajes, platos, soportes, y carcasas.

✔ Genial para 90% de tareas de mecanizado comunes.

💡 Ejemplo: Una fábrica que produce recintos electrónicos puede mecanizar eficientemente cientos de casos utilizando una configuración de 3 ejes.

Es el mecanizado de 3 ejes adecuado para ti? 🤔

✅ Elija mecanizado de 3 ejes si:

✔ Tu parte es plano o tiene formas simples.

✔ QUIERES UN rentable solución.

✔ Necesitas tiempos de respuesta rápidos.

✔ Sus materiales incluyen rieles, plástica, o madera.

❌ Considere el mecanizado de 4 ejes o 5 ejes si:

🚫 Tu parte tiene Curvas o socios complejos.

🚫 Necesitas máquina Desde múltiples ángulos sin reposicionar.

🚫 Su proyecto requiere Precisión extrema en geometrías complejas.

Desafíos y limitaciones del mecanizado de 3 ejes 🚧

Limitado a geometrías simples

- ¿Cuál es el problema??3-El mecanizado del eje es ideal para piezas planas, agujeros básicos, y cortes estándar, Pero cuando se trata de superficies curvas, bolsillos profundos, o socavos, lucha.

- Por qué? La herramienta de corte solo puede moverse Tres direcciones rectas (incógnita, Y, y Z), Entonces no puede alcanzar ángulos o características intrincadas sin voltear la pieza.

- Ejemplo: Si está haciendo una cuchilla de turbina o un componente esculpido, una máquina de 3 ejes no podrá cortar todas las características de una vez—En necesitar configuraciones adicionales.

Más configuraciones = más trabajo & Tiempo ⏳

- ¿Cuál es el problema?? Dado que las máquinas de 3 ejes solo pueden cortar desde tres direcciones, a menudo necesitas detener la máquina, reposicionar la parte, y reiniciar el proceso varias veces.

- Por qué? Cada configuración lleva tiempo, Aumenta los costos laborales, y aumenta el riesgo de desalineación.

- Ejemplo: Si está haciendo una parte compleja con características en todos los lados, Es posible que necesite 3-4 diferentes configuraciones, Cada uno que requiere un posicionamiento preciso.

No es ideal para caries profundas & Cortes internos 🔍

- ¿Cuál es el problema??3-El mecanizado del eje tiene problemas para cortar bolsillos profundos o características internas Porque la herramienta se mueve en un camino recto y no puede alcanzar fácilmente espacios confinados.

- Por qué? Cuanto más profundo sea la cavidad, Cuanto más tiempo debe ser la herramienta de corte, y Las herramientas más largas pueden doblarse o vibrar, Reducción de la precisión.

- Ejemplo: Si estás haciendo un molde con profundo, detalles intrincados, una máquina de 3 ejes puede tener dificultades para llegar a ciertas áreas sin técnicas especiales.

Requiere operadores calificados & Programadores 🎓

- ¿Cuál es el problema?? Aunque el mecanizado de 3 ejes es más simple que el mecanizado de 5 ejes, todavía requiere operadores calificados Para programar las trayectoria, Configurar piezas correctamente, y asegurar la precisión.

- Por qué? Los errores en la programación o la configuración pueden conducir a materiales desperdiciados, cortes incorrectos, y tiempos de producción más largos.

- Ejemplo: Una máquina de 3 ejes mal programada podría cortar las características críticas demasiado profundas o perderse, arruinando un bloque costoso de metal.

Menos eficiente para la producción de alta precisión o a gran escala 🏭

- ¿Cuál es el problema?? Para industrias que requieren una producción ultra alta o de producción en masa, 3-mecanizado del eje no siempre es la opción más rápida o más eficiente.

- Por qué? Ya que requiere más configuraciones y ajustes manuales, él ralentiza la producción en comparación con las máquinas múltiples avanzadas.

- Ejemplo: En fabricación aeroespacial, donde cada parte debe ser exacta, Una máquina de 5 ejes puede hacer en un solo paso lo que una máquina de 3 ejes toma múltiples pasos para lograr.

Puede desperdiciar más material & Aumentar los costos 💰

- ¿Cuál es el problema?? Porque el mecanizado de 3 ejes requiere múltiples configuraciones y cortes adicionales para llegar a ciertas áreas, a menudo resulta en más desechos materiales.

- Por qué? Corte extra significa más chips de metal, y los errores de reposicionamiento pueden provocar piezas desechadas.

- Ejemplo: Si una parte está ligeramente desalineada cuando se reposiciona, incluso por una fracción de un milímetro, Es posible que toda la pieza necesite ser descartada.

Comparación del mecanizado de 3 ejes vs. 5-Mecanizado de ejes

| Característica | 3-Mecanizado de ejes 🛠️ | 5-Mecanizado de ejes 🚀 |

| Movimiento | Se mueve incógnita, Y, z solo hachas | Se mueve incógnita, Y, z + gira alrededor de un & A hachas B |

| Complejidad de las piezas | Mejor para simple, piezas planas | Mejor para complejo, de múltiples lados, y piezas curvas |

| Tiempo de configuración | Puede requerir múltiples configuraciones para cortar diferentes lados | Cortes de Múltiples ángulos en una configuración, Reducir el reposicionamiento |

| Precisión | Bien tolerancias estándar | Mayor precisión, Ideal para aeroespacial, médico, y repuestos automotrices |

| Costo | Menor costo (máquina + mano de obra + mantenimiento) | Mayor costo Debido a la maquinaria y programación avanzadas |

| Velocidad | Más rápido para piezas simples, Pero se necesita tiempo de configuración adicional | Más rápido para partes complejas ya que reduce el reposicionamiento manual |

| Mejor utilizado para | Componentes planos, agujeros básicos, bolsillos, tragamonedas | Palas de turbina, implantes medicos, aeroespacial & piezas automotrices |

| Dificultad de programación | Más fácil de programar y operar | Requerimiento programadores calificados, software más complejo |

| Desperdicio de materiales | Más desechos debido a errores de reposicionamiento | Menos desperdicio, Uso de material más eficiente |

| Industrias que lo usan | Fabricación general, construcción, fabricación de moho | Aeroespacial, automotor, médico, prototipos de alta gama |

¿Cuál deberías elegir?? 🤔

✅ Elija mecanizado de 3 ejes si:

- Necesitas departamento, piezas simples con cortes rectos.

- Quieres una opción rentable con un cambio rápido.

- Su proyecto no requiere cortar desde múltiples ángulos.

✅ Elija el mecanizado de 5 ejes si:

- Tu diseño tiene formas complejas, curvas, o cavidades profundas.

- Necesitas Alta precisión con menos errores.

- Quieres reducir tiempo de configuración y mejorar la eficiencia.

Futuro del mecanizado de 3 ejes

Con avances tecnológicos, 3-El mecanizado del eje continúa evolucionando:

✔ AI & Aprendizaje automático - Mejora de la precisión y la automatización.

✔ Mecanizado híbrido - Combinar CNC con impresión 3D para una mejor eficiencia.

✔ Fábricas inteligentes - Internet de las cosas (IoT) Integración para el monitoreo en tiempo real.

A medida que las industrias exigen una producción más rápida y precisa, 3-El mecanizado del eje seguirá siendo un jugador clave en la fabricación moderna.

Conclusión

3-El mecanizado del eje es un piedra angular de la fabricación moderna, ofreciendo precisión, eficiencia, y versatilidad en varias industrias. Si bien no coincide con la flexibilidad del mecanizado de 5 ejes, Su asequibilidad y facilidad de uso lo convierten en una herramienta invaluable para los fabricantes de todo el mundo..

Si estás en automotor, aeroespacial, médico, o diseño de joyas, 3-El mecanizado del eje ofrece resultados confiables que mantienen la producción en el futuro. 🚀

Enlaces externos recomendados (Referencias & Lectura adicional)

Aquí hay tres fuentes confiables Para más información sobre 3-Mecanizado del eje y tecnología CNC:

1️⃣ Taller de máquinas moderna - CNC Meckining Basics - Una fuente confiable para actualizaciones, noticias, e innovaciones en mecanizado CNC.

2️⃣ Libro de cocina de CNC-Guía de 3 ejes vs. 5-Mecanizado de ejes -Un recurso detallado que explica las diferencias entre los procesos de mecanizado de múltiples eje.

3️⃣ Autodesk - CAD/CAM para mecanizado CNC - Un excelente lugar para explorar herramientas de software utilizadas en la programación y fabricación de CNC.