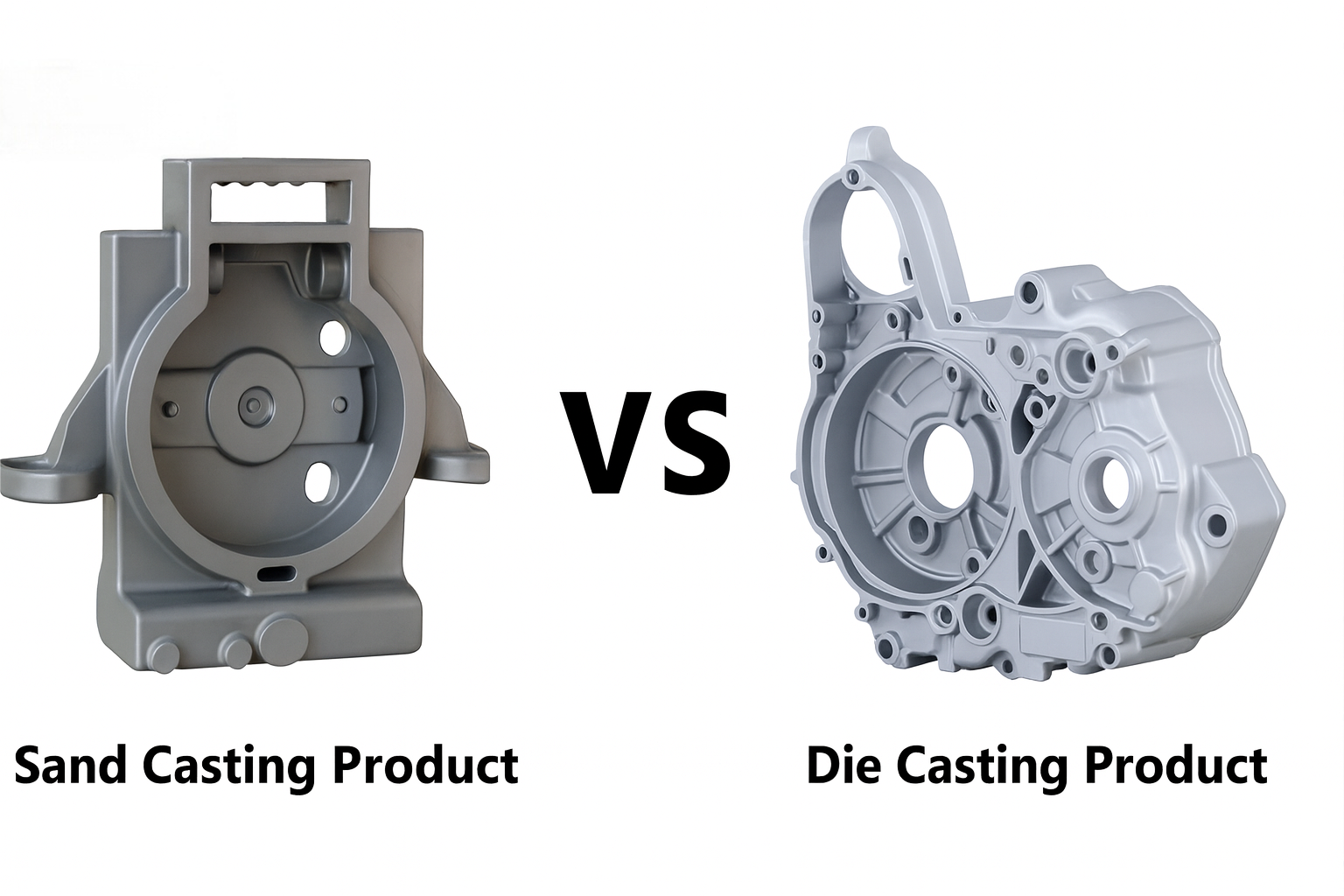

Elegir el método de fundición correcto es una decisión crítica que dicta la calidad final de un producto., costo, y viabilidad. Ambos fundición a presión y Fundición en arena Son procesos fundamentales en la fabricación de metales., pero operan bajo principios muy diferentes y atienden requisitos industriales separados. Si bien ambos logran el objetivo básico de darle al metal fundido la forma deseada, Comprender sus distintos mecanismos y compensaciones es esencial para los ingenieros de productos y especialistas en adquisiciones..

Descripción general y principios básicos

fundición a presión (Proceso de alta presión)

La fundición a presión utiliza materiales duraderos., mecanizado con precisión moldes de metal (muere). El metal fundido se inyecta en estos moldes a presión extremadamente alta (arriba a 4,500 psi) y alta velocidad. Esta presión fuerza al metal a entrar en cada cavidad del molde., creando características altamente definidas. Una vez solidificado, el dado se abre, y la parte (el casting) es expulsado.

Fundición en arena (Proceso atmosférico)

Fundición en arena, la forma más antigua de fundición, utiliza moldes creados a partir de una mezcla de arena, arcilla, y agua (o aglutinantes químicos). El metal fundido se vierte en la cavidad del molde bajo presión atmosférica (gravedad sola). Se destruye el molde de arena para recuperar la pieza terminada., y se debe preparar un nuevo molde para el siguiente ciclo..

Diferencias clave en detalle

La selección a menudo depende de una comparación profunda entre siete parámetros clave:

A. Material de herramientas y durabilidad

fundición a presión: los moldes de metal (muere) están hechos de acero para herramientas endurecido, Diseñado para soportar miles de ciclos.. Esta alta durabilidad es la base de la eficiencia del proceso para la producción en masa..

Fundición en arena: Los moldes son efímeros y están hechos de arena compactada., diseñado para un solo uso. el patrón (Se utiliza para crear la cavidad en la arena.) puede ser madera, plástico, o metal, ofreciendo costos iniciales más bajos.

B. Volumen de producción y costos de herramientas

| Parámetro | Fundición en arena | fundición a presión |

| Costo de herramientas (Inicial) | Bajo (típicamente $500 a $8,000) | Alto (típicamente $8,000 a $80,000 o más) |

| Tiempo de ciclo | Lento (Incluye de 5 a 10 minutos para la preparación/destrucción del molde.) | Rápido (Ciclos medidos en segundos/minutos.) |

| Volumen Ideal | Bajo a medio (Prototipos, 1 a 500 unidades) | Producción en masa de alto volumen (Miles a millones) |

| Costo por pieza | Más alto | Muy bajo (debido al tiempo de ciclo rápido) |

C. Exactitud y precisión dimensional

La alta presión utilizada en la fundición a presión es crucial para la precisión.

fundición a presión: Logra precisión dimensional superior (tolerancias a menudo dentro de ± 0.05 mm en ± 0.15 milímetros. Esta precisión a menudo minimiza o elimina la necesidad de costosos post-mecanizados..

Fundición en arena: Menor precisión (tolerancias típicas ± 0.8 mm en ± 1.5 milímetros). El proceso da como resultado un ajuste más holgado y requiere mayor tolerancias de mecanizado (Material adicional añadido para el posterior mecanizado CNC.).

D. Acabado de superficie y espesor de pared

Acabado de la superficie:

fundición a presión: Produce un excelente, acabado suave (tan bajo como 1 µm) justo fuera del molde, a menudo no requiere acabado.

Fundición en arena: Deja un grueso, superficie rugosa debido a la textura del molde de arena, requiriendo una limpieza exhaustiva, molienda, o granallado.

Espesor de la pared:

fundición a presión: Capaz de producir muy paredes delgadas (tan delgado como 0.5 milímetros), permitiendo diseños livianos.

Fundición en arena: Circunscrito a paredes más gruesas (típicamente 3 mm o más) para garantizar un flujo adecuado y evitar defectos de solidificación.

mi. Calidad y Fortaleza Interna

fundición a presión: La inyección a alta presión minimiza la porosidad interna. (espacios de aire). Esto da como resultado una más densa, parte más fuerte con propiedades mecánicas superiores y una estructura interna más consistente.

Fundición en arena: Dado que el metal se vierte por gravedad., Las bolsas de aire y la porosidad son comunes.. Si bien la resistencia general del material puede ser comparable, el riesgo de defectos internos es mayor, que puede afectar la consistencia y la vida de fatiga.

F. Selección de materiales y restricciones de tamaño

Limitaciones de materiales (Amabilidad de la aleación):

fundición a presión: Limitado principalmente a aleaciones de bajo punto de fusión como el aluminio (Alabama), Zinc (zinc), Magnesio (magnesio), y cobre (Cu) aleaciones. Metales ferrosos de alto punto de fusión (como el acero) son generalmente incompatibles porque dañarían rápidamente el troquel metálico.

Fundición en arena: Altamente versátil y amigable con las aleaciones. Se puede utilizar durante casi cualquier metal, incluidas aleaciones ferrosas de alta temperatura como acero y hierro fundido, ya que el molde de arena se destruye después de un uso.

Restricciones de tamaño:

fundición a presión: Generalmente limitado a piezas de tamaño pequeño a mediano (p.ej., bloques de motor, casos de transmisión, carcasas).

Fundición en arena: Ideal para componentes muy grandes (p.ej., carcasas de bombas masivas, grandes bases de máquinas, hélices de barco), ya que el tamaño del molde se puede escalar fácilmente.

Seleccionar el proceso correcto

La elección óptima se determina priorizando los requisitos clave del componente final.:

| Si su requisito principal es... | Elegir… | Razón fundamental |

| Alto volumen de producción | fundición a presión | Tiempo de ciclo más rápido (mayor rendimiento). |

| Bajo presupuesto de herramientas / Inicio rápido | Fundición en arena | Inversión inicial mínima y creación rápida de patrones.. |

| Acabado superficial superior / Paredes delgadas | fundición a presión | La inyección a presión crea superficies lisas y permite diseños más delgados.. |

| Acero fundido o hierro fundido | Fundición en arena | Puede soportar la alta temperatura de fusión de las aleaciones ferrosas.. |

| Tamaño de pieza muy grande | Fundición en arena | Tamaño de molde escalable y menor costo por unidad de volumen para componentes masivos. |

| Tolerancias estrictas & Mecanizado mínimo | fundición a presión | Precisión inherentemente mayor y excelente repetibilidad. |

Aplicaciones Típicas

Aplicaciones de fundición a presión: Automotor (soportes del motor, carcasas de transmision, pistones), Electrónica (disipadores de calor, recintos), Herramientas eléctricas, Dispositivos médicos, y juguetes.

Aplicaciones de fundición en arena: válvulas grandes, bloques de motor, marcos de equipos agrícolas, bases de máquina herramienta, y cualquier especializado o prototipo pieza necesaria de forma rápida y económica.

En resumen, La fundición a presión es una técnica de alta velocidad., solución de alta precisión para grandes volúmenes, piezas pequeñas a medianas, mientras La fundición en arena es flexible, opción de menor costo para prototipos, carreras de bajo volumen, y componentes muy grandes hecho de cualquier aleación.

Preguntas frecuentes

1. ¿Por qué la fundición a presión generalmente se limita a aleaciones de bajo punto de fusión como el aluminio y el zinc??

Usos de la fundición a presión troqueles de metal hecho de acero endurecido. Si los metales de alto punto de fusión (como acero o hierro fundido) se usaron, El calor extremo haría que las matrices de metal se erosionaran rápidamente. (un proceso llamado fatiga térmica o “control de calor”), reduciendo drásticamente la vida útil del troquel y aumentando los costos de mantenimiento. Por lo tanto, La fundición a presión es rentable sólo con aleaciones que tienen temperaturas de fusión más bajas., como el aluminio (Alabama), Zinc (zinc), y magnesio (magnesio).

2. ¿Pueden las piezas fundidas en arena lograr la misma precisión que las piezas fundidas a presión si se realiza un posmecanizado??

Durante el posmecanizado (p.ej., usando CNC) Puede corregir las imprecisiones dimensionales y el acabado superficial rugoso de las piezas fundidas en arena., logrando el mismo nivel de precisión como un talentoso La pieza fundida a presión es a menudo poco práctico y caro. Las piezas fundidas en arena requieren una gran margen de mecanizado (material extra) para compensar las variaciones de lanzamiento. La eliminación de este material mediante CNC añade tiempo y costes significativos, a menudo anulando los ahorros iniciales del proceso de fundición en arena..

3. ¿Cuál es la principal causa del acabado superficial rugoso en la fundición en arena??

La rugosidad en la fundición en arena es causada por la material del molde en sí. Las partículas de arena utilizadas para crear la cavidad son relativamente gruesas.. Cuando el metal fundido llena la cavidad., La textura de su superficie refleja la textura gruesa de los granos de arena., dando como resultado un mate, granular, y superficie irregular.

4. ¿Por qué hay defectos internos? (porosidad) más común en fundición en arena que en fundición a presión?

En fundición de arena, el metal se vierte debajo gravedad (presión atmosférica). Durante la solidificación, las burbujas de gas pueden quedar atrapadas, o se pueden formar cavidades por contracción con relativa facilidad, conduciendo a porosidad. En fundición a presión, el presión de inyección extremadamente alta compacta el metal a medida que se solidifica, expulsando el aire y los gases y resultando en una masa mucho más densa., estructura interna más sólida estructuralmente con porosidad mínima.

5. Para la producción de bajo volumen de una gran parte., ¿Qué factor hace que la fundición en arena sea más barata a pesar de su lento tiempo de ciclo??

Para tiradas de bajo volumen de piezas grandes, el alto costo de crear un duradero, precisión morir de metal para la fundición a presión se convierte en un gasto abrumador. La fundición en arena es más barata porque las herramientas (el patrón usado para hacer el molde de arena) A menudo está hecho de materiales económicos como la madera., plástico, o espuma, Representa una inversión de capital mínima en comparación con la enorme matriz de acero requerida para el proceso alternativo..

6. ¿En qué se diferencia la velocidad de enfriamiento entre los dos procesos?, y por qué importa?

fundición a presión: El metal fundido entra en contacto con un frío., denso molde metálico, resultando en muy enfriamiento rápido. Este enfriamiento rápido a menudo produce una estructura de grano más fina cerca de la superficie. (una “zona de relajación”), que puede mejorar la dureza y la resistencia de la superficie.

Fundición en arena: El metal fundido está rodeado de poros., aislante arena, resultando en mucho velocidad de enfriamiento más lenta. El enfriamiento lento produce una estructura de grano más gruesa y puede aumentar el riesgo de defectos internos..

7. Al considerar la sostenibilidad, ¿Qué proceso es más respetuoso con el medio ambiente??

Ambos procesos tienen factores ambientales.:

fundición a presión: Consume mucha energía debido a la necesidad de mantener calientes las matrices metálicas grandes y al sistema de alta presión.. Sin embargo, Los troqueles metálicos son reutilizables para cientos de miles de piezas..

Fundición en arena: El principal desperdicio es el gran volumen de residuos gastados., arena usada que debe desecharse o reciclarse.

Generalmente, La fundición a presión se considera más sostenible para la producción en masa debido al extremadamente bajo desperdicio de material., alta repetibilidad, y la larga vida útil de la herramienta dan como resultado menos desperdicio general por pieza producida en comparación con el consumo continuo de arena en el proceso alternativo..