L'usinage CNC en verre a révolutionné la façon dont les composants de précision sont fabriqués, permettant aux concepteurs et aux ingénieurs de réaliser des géométries complexes et des tolérances serrées qui étaient auparavant peu pratiques, voire impossibles. Des dispositifs microfluidiques aux grands panneaux architecturaux, Le verre usiné CNC offre une précision exceptionnelle, répétabilité, et finition de surface. Ce guide approfondit les méthodes, matériaux, avantages, et considérations sur l'usinage CNC du verre, vous permettant de prendre des décisions éclairées pour votre prochain projet.

Le verre peut-il être usiné CNC?

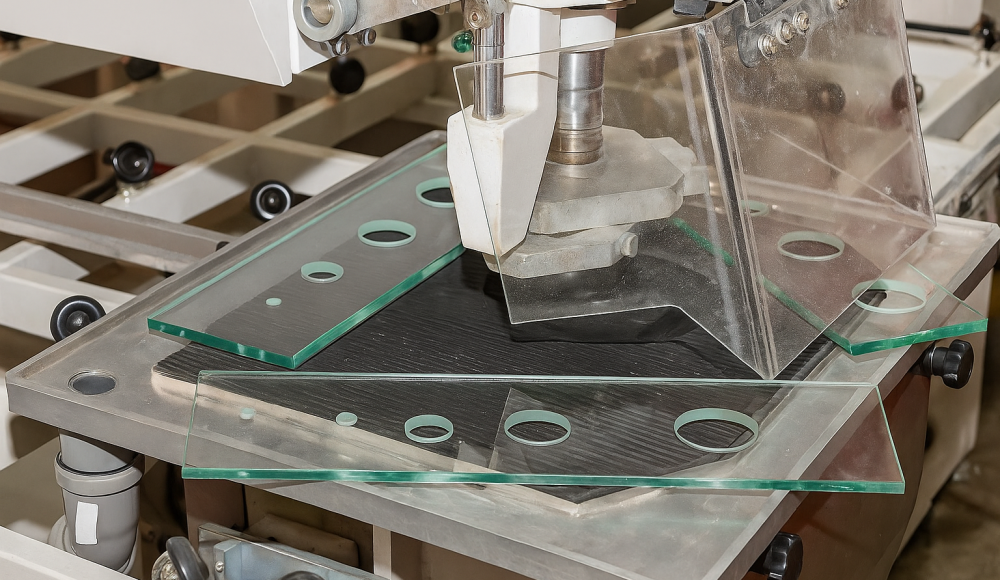

Oui : progrès en matière de rigidité des machines-outils, conception de broche, outillage, et le contrôle des processus permettent désormais d'usiner le verre CNC de manière fiable. Cependant, la fragilité et la dureté inhérentes du verre nécessitent des techniques et des outils spécialisés pour minimiser l'écaillage, craquage, et l'usure des outils. Avec un montage approprié, livraison de liquide de refroidissement, et optimisation des paramètres, L'usinage CNC peut produire des coupes complexes, trous, et textures de surface des panneaux et composants en verre.

Comment fonctionne l'usinage du verre CNC?

L'usinage CNC du verre suit le flux de travail standard CAD → CAM → CNC, mais avec des adaptations critiques pour le comportement matériel.

Cad to Cam Workflow

Conception & Tolérance

Créer des modèles 3D en CAO, spécification des dimensions géométriques et des tolérances (DG&T).

Identifier les surfaces critiques (par exemple., visages optiques) nécessitant une planéité ou une rugosité submicronique.

Génération de parcours d'outil

Dans le logiciel de FAO, sélectionner les parcours d'outils appropriés (contouring, empocher, forage).

Définir le pas à pas, abaissement, taux d'avance, et vitesses de broche optimisées pour le retrait du verre.

Configuration de la machine

Fixation

Utiliser des mandrins à vide, tampons adhésifs, ou des mâchoires souples pour soutenir le verre sans provoquer de contraintes.

Assurer un support uniforme pour éviter les vibrations et les fissures.

Outillage & Broche

Utiliser des fraises en bout diamantées, exercices, et outils de meulage/bavure.

Broches à grande vitesse (≥ 30,000 RPM) réduire les forces de coupe et améliorer la finition de surface.

Liquide de refroidissement & Contrôle de la poussière

Le liquide de refroidissement ou la microlubrification minimisent l'accumulation de chaleur et éliminent les débris..

Les systèmes d'extraction intégrés capturent la poussière de verre pour éviter les rayures sur la surface.

Opérations d'usinage

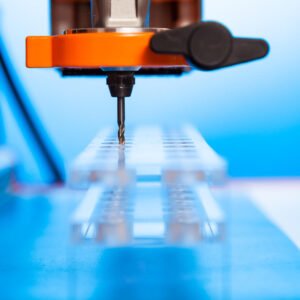

Passes d'ébauche

Commencez par des profondeurs de coupe prudentes (par exemple., 0.1–0,2 mm) à des vitesses d'alimentation modérées pour éliminer en douceur les matériaux en vrac.

Passes de finition

Passer à des abaisseurs fins (≤ 0.05 mm) et avance réduite pour atteindre la rugosité de surface cible (< Râ 0.2 µm).

Surveillance en cours de processus

Utilisez des capteurs de vibrations et un retour acoustique pour détecter l’usure des outils ou les fissures des pièces en temps réel.

Étapes de post-usinage

Polissage

Le polissage secondaire avec des tampons diamantés fins ou une boue peut améliorer encore la clarté optique..

Trempe/Renforcement

Le renforcement thermique ou chimique améliore la ténacité, critique pour les composants porteurs ou de sécurité.

Inspection finale

Machines à mesurer tridimensionnelles (CMMS), interféromètres, et les profilomètres de surface vérifient les spécifications géométriques et de surface.

Techniques utilisées dans l'usinage CNC du verre

Les propriétés uniques du verre nécessitent une boîte à outils diversifiée de techniques d’usinage:

Fraisage & Contouring

Enlève de la matière pour former des bords, niches, et formes 3D avec des fraises diamantées.

Forage & Ennuyeux

Crée des trous précis à partir du sous-marin-0.5 mm à plusieurs millimètres à l'aide de forets et d'alésoirs diamantés.

Gravure & Poche

Les tailleurs de diamant sculptent des motifs décoratifs, numéros de série, ou des poches peu profondes pour les joints.

Rainurage & Rainurage

Forme des canaux étroits pour les joints ou les éléments d'assemblage; critique dans les applications de manipulation de fluides.

Affûtage & Clapotis

Techniques de raffinement de surface qui intègrent la planéité et la rugosité dans les tolérances optiques.

Découpe jet d'eau (Systèmes hybrides)

La tête à jet d'eau abrasive sur une plate-forme CNC permet d'obtenir des profils 2D sans contrainte thermique.

Renforcement thermique/chimique

Les traitements post-usinage (bains échangeurs d'ions ou fours de trempe) augmentent la compression de surface et la durabilité..

Types de verre adaptés à l'usinage CNC

| Type de verre | Propriétés clés | Utilisations courantes |

| Borosilicate | Faible extension thermique, haute résistance chimique | Matériel de laboratoire, optique de précision |

| Chaux sodée | Économique, usinable, force modérée | Panneaux architecturaux, éléments décoratifs |

| Silice fondue | Expansion ultra-faible, haute clarté | Plaquettes semi-conductrices, optique haute puissance |

| Aluminosilicate | Haute résistance, bonne stabilité thermique | Écrans de smartphones, couvertures d'affichage durables |

| Verre au Plomb | Indice de réfraction élevé, dense | Verres de précision, prisme |

| Quartz | Pureté exceptionnelle, Transparence UV, résistance à la chaleur élevée | Lampes UV, fenêtres de processus de semi-conducteurs |

Avantages de l'usinage CNC du verre

Haute précision & Répétabilité

Obtenez des tolérances de ± 10 µm de manière constante sur tous les lots.

Géométries personnalisées complexes

Produire des contre-dépouilles, microcanaux, et surfaces de forme libre dans une seule configuration.

Finition de surface supérieure

Ra jusqu'à 0.05 µm sans polissage manuel approfondi.

Efficacité matérielle

Perte de saignée et rebuts minimisés grâce à des parcours d'outils et à une imbrication optimisés.

Automatisation & Sécurité

La commande CNC réduit l'exposition de l'opérateur aux éclats de verre; les options de chargement automatisé augmentent le débit.

Limites de l'usinage CNC du verre

Risque de fragilité

Sections fines (< 2 mm) et les coins serrés peuvent se fissurer sous l'effet du stress.

Équipement & Coût d'outillage

Les broches de haute précision et les outils diamantés nécessitent des investissements importants.

Expertise de l'opérateur

Nécessite une formation spécialisée en comportement du verre, sélection d'outillage, et réglage des processus.

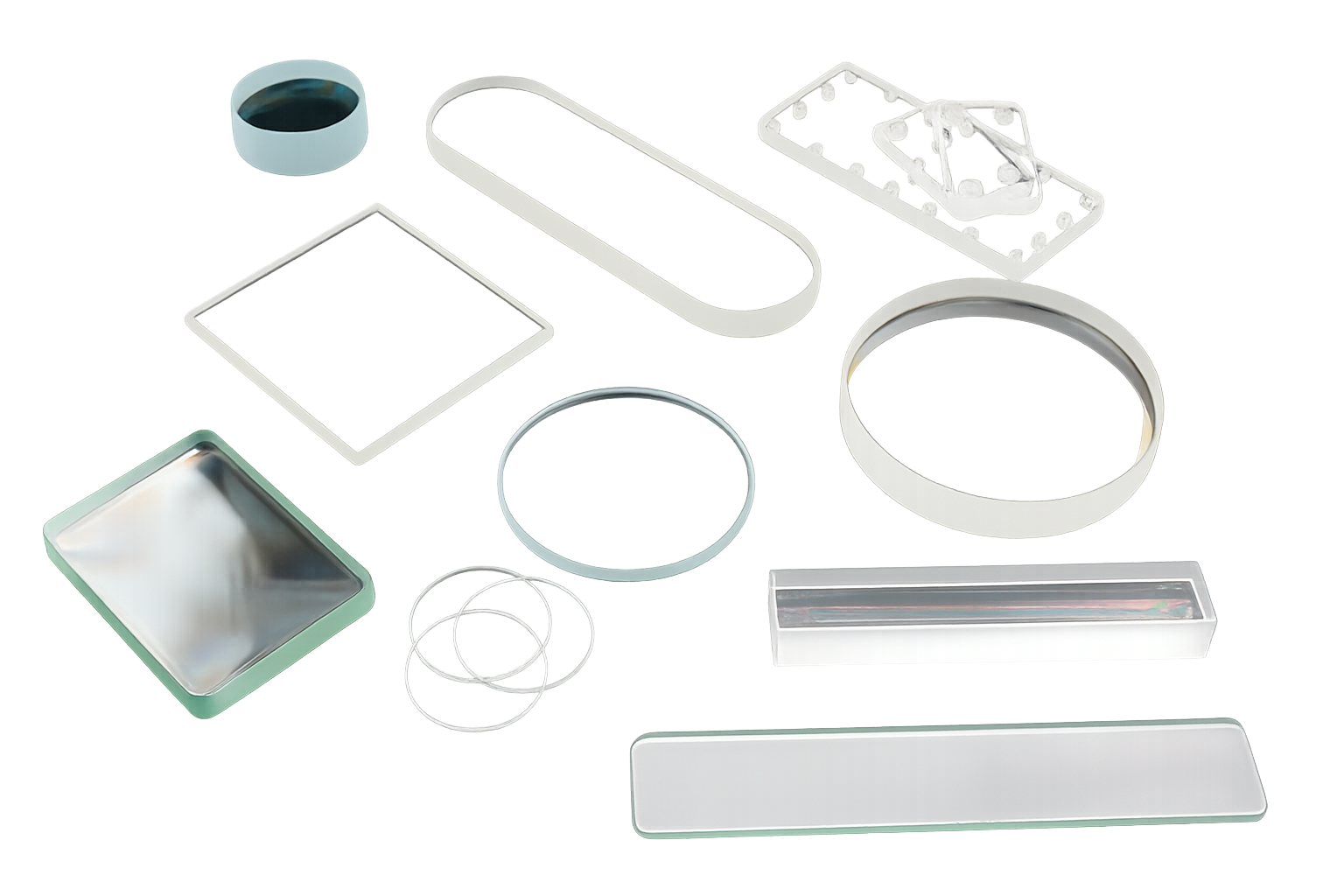

Applications de l'usinage CNC du verre

Optique & Photonique

Lentilles, prisme, guides de vagues, et éléments de mise en forme de faisceau.

Équipement semi-conducteur

Substrats de plaquettes, fenêtres d'alignement de masque, et housses de protection.

Médical & Biotechnologie

Puces microfluidiques, lumières du cathéter, chambres à lames de diagnostic.

Aérospatial & Défense

Fenêtres à pression, boîtiers de capteurs, et fenêtres haute température.

Electronique grand public

Couvertures d'écran tactile, couvre-objectifs d'appareil photo, et pièces décoratives en verre.

Architectural & Décoratif

Panneaux de verre dépoli, luminaires, et installations artistiques.

Considérations relatives aux coûts

Dépenses en capital

Machine CNC avec broche à grande vitesse: $150,000–500 000$+.

Outillage diamanté: $100–500$ par coupeur.

Coûts d'exploitation

Salaires des opérateurs qualifiés, liquide de refroidissement, usure des outils, et entretien.

Économie de volume

Des volumes plus élevés compensent les coûts d’installation; les petites séries comportent une prime par pièce.

Complexité de conception

Des fonctionnalités complexes augmentent le temps de cycle; équilibre entre les ambitions de conception et le budget.

Comparaison avec d'autres méthodes de fabrication du verre

| Aspect | Usinage CNC | Découpe au laser | Techniques manuelles |

| Précision | ±10 µm | ±50–100 µm | ±100–300 µm |

| 3Capacité D | Contours et contre-dépouilles 3D complets | Profils principalement 2D | Formes limitées |

| Contrainte thermique | Minimal (avec liquide de refroidissement) | Microfissures potentielles | Faible mais incohérent |

| Temps d'installation | Modéré (Programmation FAO) | Faible | Très faible |

| Finition de surface | Ra 0,05–0,2 µm | Ra 1-3 µm | Râ > 3 µm |

Sélection d'un fournisseur d'usinage CNC pour le verre

Équipement & Certifications

Recherchez l'ISO 9001:2015, AS9100 pour l'aérospatiale, ou ISO/CEI 17025 pour la métrologie.

Expertise technique

Revoir des études de cas en optique, médical, ou industries des semi-conducteurs.

Contrôle de qualité

Sondage en cours, Inspection CMM, interférométrie, et profilométrie de surface.

Délai de mise en œuvre & Capacité

Confirmer les capacités de débit et les plans de sauvegarde pour les exécutions urgentes.

Services de post-traitement

Polissage, tremper, enrobage, et intégrations d'assemblage.

Étude de cas: Précision au sommetProcessus d'usinage CNC du verre

Inspection entrante

Vérifier le type de verre, épaisseur, et précertifier la planéité par interférométrie laser.

Optimisation du parcours d'outil

Utilisez des modèles de FAO internes optimisés pour un engagement minimal de l'outil et un contrôle des vibrations.

Usinage en plusieurs étapes

Coupe grossière à 20,000 RPM; terminer la passe à 40,000 RPM avec 1 µm abaisseur.

Amélioration des surfaces

Polissage en suspension de diamant ou renforcement par échange d'ions en option.

Assurance qualité finale & Conditionnement

MMT et inspection optique; caisse sur mesure avec mousse amortissant les vibrations.

Conclusion

L'usinage CNC du verre comble le fossé entre l'ambition de conception et la fabricabilité, libérer des prouesses de précision et de complexité qui stimulent l’innovation dans tous les secteurs. En comprenant les nuances de la sélection des outils, paramètres du processus, et comportement des matériaux, vous pouvez exploiter l'usinage CNC pour produire des composants en verre qui répondent aux normes les plus strictes en matière de performance et d'esthétique. Lors de l'évaluation des partenaires, privilégier l’expertise technique, systèmes de qualité, et une expérience éprouvée dans la fabrication du verre, comme celle démontrée par Tops Precision, pour garantir le succès de votre projet, du prototype à la production..

En savoir plus:

Services d'usinage de précision