Polycarbonate (PC) Le moulage par injection est l'une des méthodes les plus largement utilisées pour produire des matériaux solides., transparent, and precise plastic components across industries. This engineering-grade thermoplastic is known for its unique combination of toughness, résistance à l'impact, and optical clarity, making it the go-to choice for medical, automobile, consommateur, and optical applications.

Dans cet article, we will take a detailed look at the fundamentals of polycarbonate injection molding, ses applications, techniques, avantages, défis, and common problems that manufacturers must address when working with this versatile plastic.

Polycarbonate Injection Molding Basics

Polycarbonate Injection Molding Basics

Polycarbonate injection molding is the process of injecting melted polycarbonate pellets into a mold under high temperature and pressure to form complex shapes. Polycarbonate itself is an amorphous thermoplastic polymer with carbonate functional groups, known for its high transparency, durabilité, et résistance à la chaleur.

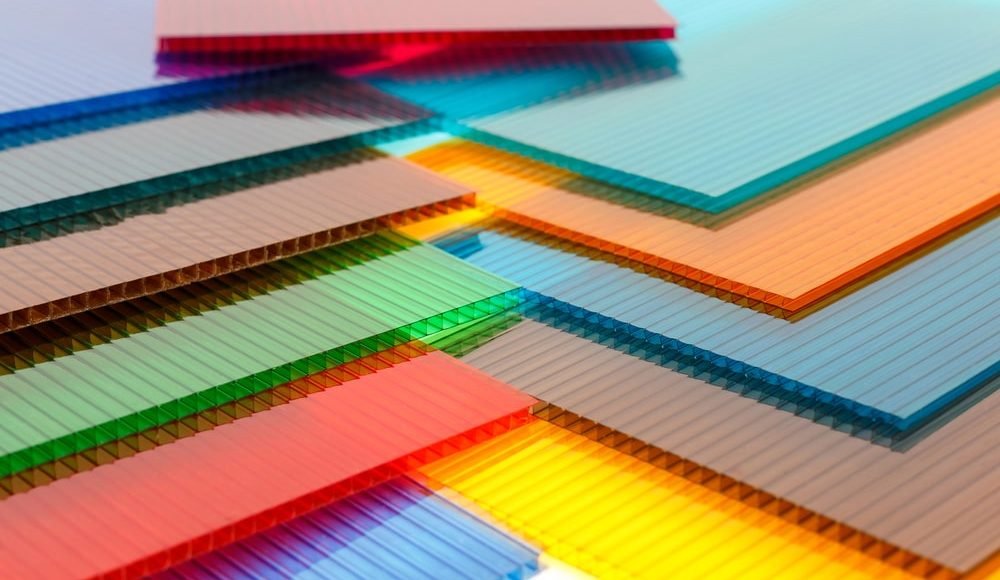

While polycarbonate can also be processed by extrusion, blow molding, and thermoforming, moulage par injection offers the highest level of flexibility in terms of part geometry, production de masse, et qualité de surface. Compared to acrylic, polycarbonate provides better toughness, résistance à l'impact, et stabilité thermique, while still maintaining excellent optical clarity.

Applications of Polycarbonate Injection Molding

Due to its unique balance of mechanical and optical properties, polycarbonate injection molding finds use in a wide range of industries:

Eyeglasses and Lenses

Polycarbonate is the preferred choice for optical lenses, including eyeglasses, sunglasses, and safety goggles. C'est léger, resists UV radiation when stabilized, and has excellent clarity.

Équipement médical

Its ability to withstand sterilization (autoclavage à vapeur, ethylene oxide, gamma irradiation) makes polycarbonate suitable for syringes, IV connectors, catheters, and incubators. The transparency of the material is vital for monitoring fluids and medical processes.

Produits de consommation

Polycarbonate is food-safe and resistant to high temperatures, making it ideal for kitchenware such as mixing bowls, food processor housings, and water bottles. It can be manufactured in transparent or opaque forms depending on product requirements.

Applications automobiles

Polycarbonate is widely used in headlight lenses, supports d'instruments, and interior trim due to its impact resistance, UV stability, and ability to withstand temperature fluctuations. Unlike glass, it resists shattering, providing safety benefits.

The Polycarbonate Injection Molding Process

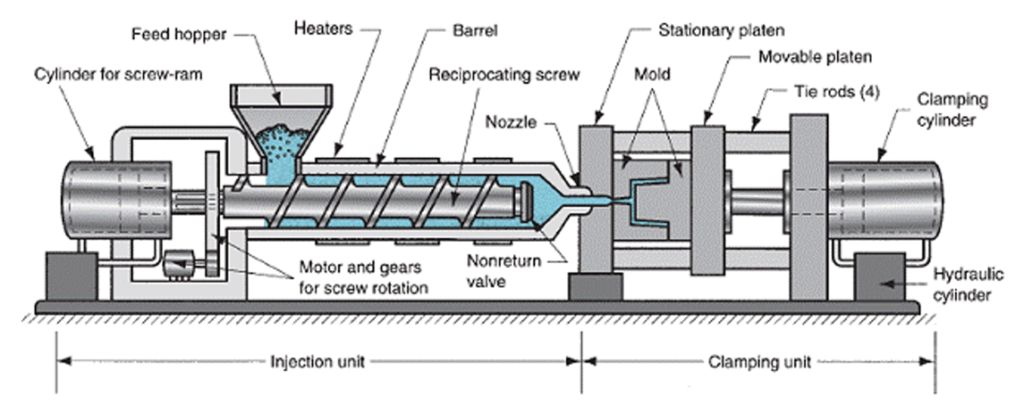

The process is similar to injection molding with other thermoplastics but requires specific attention to heat and viscosity control:

Alimentation & Fusion: Polycarbonate pellets are dried and then fed from a hopper into a heated barrel. Friction and heat generated by the screw melt the material.

Injection: Once melted, the screw pushes the molten polymer into the mold cavity at high pressure.

Refroidissement & Solidification: The part cools inside the mold, shrinking slightly as it solidifies.

Éjection: The mold opens and the part is ejected for finishing.

Because polycarbonate has high viscosity, it requires higher processing temperatures (260–320 °C) and careful injection speed control to avoid material degradation.

Polycarbonate Injection Molding Techniques

Different specialized techniques are often applied to improve part quality and reduce molding challenges:

Rapid Heating & Refroidissement (RH&C)

Prevents weld lines and surface blemishes on transparent parts by heating the mold before injection and cooling it rapidly afterward.

Water-Assisted Injection Molding

Used for hollow or thin-walled parts. High-pressure water inside the mold pushes plastic against the cavity walls for uniform thickness and smooth interiors.

Compression Injection Molding

Suitable for thick-walled parts prone to sink marks. Plastic is injected at low pressure into an open mold, which then closes to form the final part.

Overmolding/Insert Molding

Allows multiple materials to be combined into one component by molding polycarbonate over pre-placed inserts or secondary materials.

Advantages of Polycarbonate Injection Molding

Polycarbonate injection molding offers numerous benefits for manufacturers:

Fast Cycle Times – Much quicker than machining or thermoforming, enabling high productivity.

Précision & Tolérances strictes – Consistency of ±0.1 mm can be achieved with well-designed molds.

Wide Size Range – Suitable for both small intricate parts and larger automotive components.

Excellent Repeatability – High consistency across thousands or millions of parts.

Finition de surface de haute qualité – Mold surfaces can be polished to transfer mirror-like clarity.

Efficient Material Usage – Un minimum de déchets, with runners often recyclable.

Low Labor Costs – Highly automated process reduces reliance on manual labor.

Flexibilité de conception – Allows creation of complex geometries, multi-material parts, and functional designs.

Disadvantages of Polycarbonate Injection Molding

Malgré ses avantages, several challenges exist:

High Tooling Costs: Molds are expensive to design, machine, and polish, making low-volume production uneconomical.

Expensive Raw Material: Polycarbonate is costlier than alternatives like polypropylene or ABS.

Processing Difficulties: High viscosity makes thin-walled or detailed parts harder to mold without risking degradation.

Common Problems in Polycarbonate Injection Molding

To ensure successful production, manufacturers must address common issues:

Absorption d'humidité

Polycarbonate absorbs moisture quickly, leading to splaying and weakened properties. Pellets must be dried to less than 0.02% teneur en humidité avant le traitement.

Adhesion to Metals

PC tends to stick to molds or screws with high iron content. Chrome plating or special coatings help prevent sticking.

High Viscosity Challenges

Requires higher temperatures and injection pressures, but excessive heat may cause yellowing or chemical breakdown. Careful balance is essential.

Other Materials for Injection Molding

Other Materials for Injection Molding

While polycarbonate is popular, many other thermoplastics are also injection molded:

abdos (Acrylonitrile Butadiène Styrène) – Good for consumer products and automotive trim.

PP (Polypropylène) – Widely used in packaging, automobile, and household goods.

Nylon (Pennsylvanie) – Strong and wear-resistant, suitable for gears and mechanical components.

Filled Plastics – Polycarbonate and other resins can be reinforced with glass fibers or carbon fibers for added strength.

Metal Injection Molding (MIM) – Uses a polymer binder mixed with metal powders, followed by sintering.

Résumé

Polycarbonate injection molding combines strength, transparence, et précision, making it one of the most valuable processes in modern manufacturing. From medical devices and eyewear to automotive headlights and consumer goods, PC injection molding continues to expand its applications.

Although the material and tooling costs can be high, the process offers unmatched évolutivité, répétabilité, and design flexibility for high-performance plastic parts. With proper drying, conception de moule, and process control, manufacturers can overcome the challenges of viscosity and moisture sensitivity to produce flawless, high-quality polycarbonate components.

FAQ

- What is the ideal processing temperature for polycarbonate injection molding?

Polycarbonate typically requires processing temperatures between 260–320 °C. The exact range depends on the grade of the resin, the part geometry, and the machine being used. Careful monitoring is necessary because prolonged exposure to high temperatures can cause yellowing or chemical degradation. - Why must polycarbonate pellets be dried before injection molding?

Polycarbonate is highly hygroscopic, meaning it absorbs moisture from the air. If not dried properly, the moisture will turn into steam during molding, caution splay marks, streaks, and reduced mechanical strength. Pellets should be dried to a moisture content below 0.02%avant le traitement. - Can polycarbonate be overmolded with other plastics or materials?

Oui. Polycarbonate is often used in overmolding or insert molding processeswhere it bonds with elastomers (like TPU) or structural plastics (like ABS). This enables multi-material designs, such as soft-touch grips on rigid housings. Proper mold design and material compatibility must be considered for strong bonding. - How does polycarbonate compare to acrylic in injection molding?

Both materials are transparent, but polycarbonate has superior impact resistance, dureté, et résistance à la chaleur, while acrylic offers better scratch resistance and lower cost. Polycarbonate is often preferred for safety-critical parts such as safety goggles, automotive lenses, et dispositifs médicaux. - What are common defects in polycarbonate injection molding and how can they be prevented?

Some common defects include:

Splay/Blisters: Caused by moisture; preventable by proper drying.

Burn Marks: Due to trapped gases; solved with better venting.

Lignes de soudure: Occur in transparent parts; minimized using Rapid Heating & Refroidissement (RH&C) techniques.

Yellowing: Results from excessive heat exposure; mitigated by precise temperature control.