In today’s industries, CNC milling is used for everything from aerospace turbine blades and medical implants to automotive transmission housings and consumer electronics. What makes it so versatile is that there isn’t just one milling method—there are multiple milling operations, each suited for specific shapes, surfaces, and finishes. By choosing the right one, manufacturers ensure efficiency, accuracy, and quality.

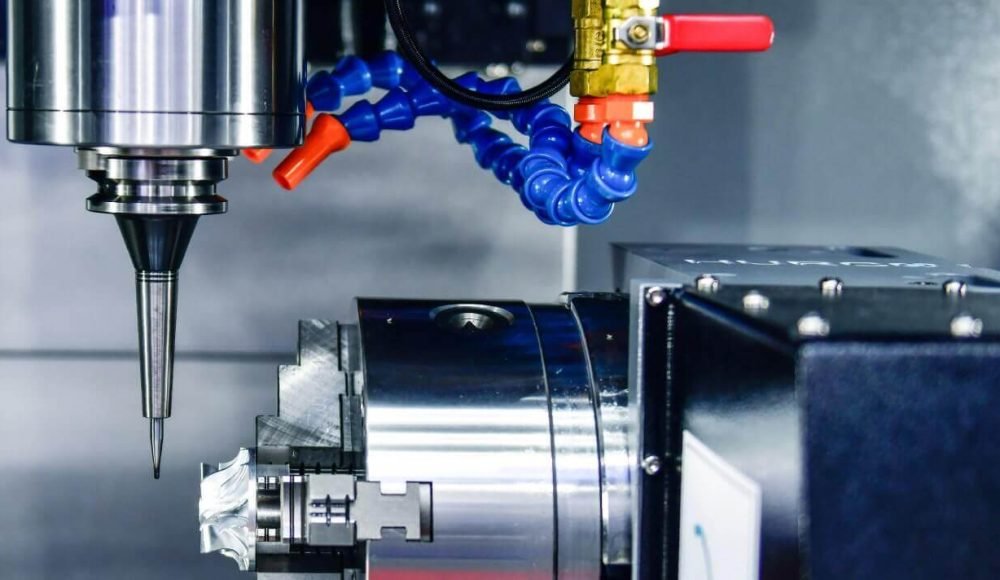

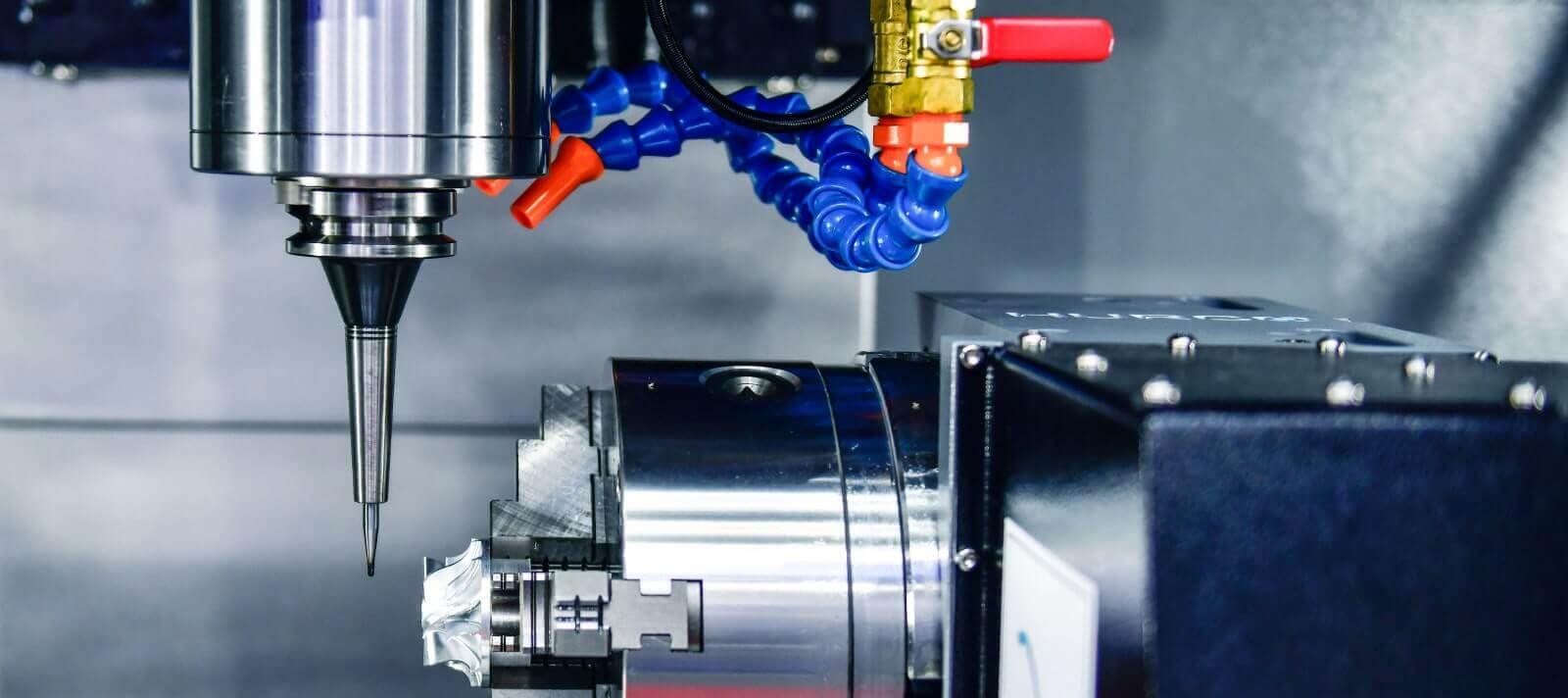

Before we dive into the different operations, it’s essential to understand how CNC milling actually works and what components make it possible.

How CNC Milling Works

The CNC milling process might sound complicated, but it’s easier to understand if we break it down into steps. At its simplest, the process begins with a design and ends with a finished part. Let’s go through the main stages:

Designing the Part – Engineers or designers create a digital 3D model of the component using CAD (Computer-Aided Design) software. This serves as the blueprint.

Converting Design to Code – The CAD model is translated into G-code and M-code, which are machine instructions that the CNC system understands. These codes control every aspect of the process, from spindle speed to cutting depth.

Tooling & Setup – The operator mounts the correct cutting tools on the spindle and secures the raw material (the workpiece) on the work table. Fixtures, clamps, or vices are used for stability.

Execution – The CNC machine follows the programmed instructions, moving the spindle and cutting tools across the workpiece to remove material layer by layer until the desired geometry is achieved.

This process can be repeated endlessly with consistent results, making CNC milling one of the backbones of mass production today.

Advantages of CNC Milling

So why do manufacturers choose CNC milling over other machining methods? The reasons are many, and each one contributes to why this process is such a game-changer in industries around the world.

Unmatched Precision and Accuracy

CNC milling can achieve tolerances as tight as ±0.01 mm. This level of accuracy is impossible to achieve consistently with manual operations. Whether producing a single prototype or thousands of identical units, CNC milling guarantees precision.

Repeatability and Consistency

Once a program is created, it can be used to manufacture identical parts again and again without variation. This makes CNC milling ideal for industries like aerospace, automotive, and electronics, where uniformity is critical.

Flexibility Across Materials

CNC milling can handle a wide range of materials—from metals like steel, aluminum, and titanium to plastics, composites, and even wood. This versatility makes it suitable for countless applications.

Complex Geometries Made Simple

With multi-axis CNC milling (3, 4, 5, or even 6 axes), it’s possible to produce complex geometries such as turbine blades, intricate molds, and precision implants. These would be extremely difficult or impossible with conventional machining.

Reduced Labor and Time

Traditional machining requires constant manual adjustments. CNC milling, on the other hand, runs automatically once set up, reducing the need for supervision and minimizing human error.

Enhanced Productivity

Because CNC machines can run 24/7, production doesn’t need to stop. This increases throughput and shortens lead times.

High-Quality Surface Finishes

Different milling operations can produce varying levels of smoothness. Operations like face milling deliver very fine surface finishes, reducing the need for secondary finishing processes.

Put simply, CNC milling combines speed, precision, and flexibility—qualities that make it indispensable for modern manufacturing.

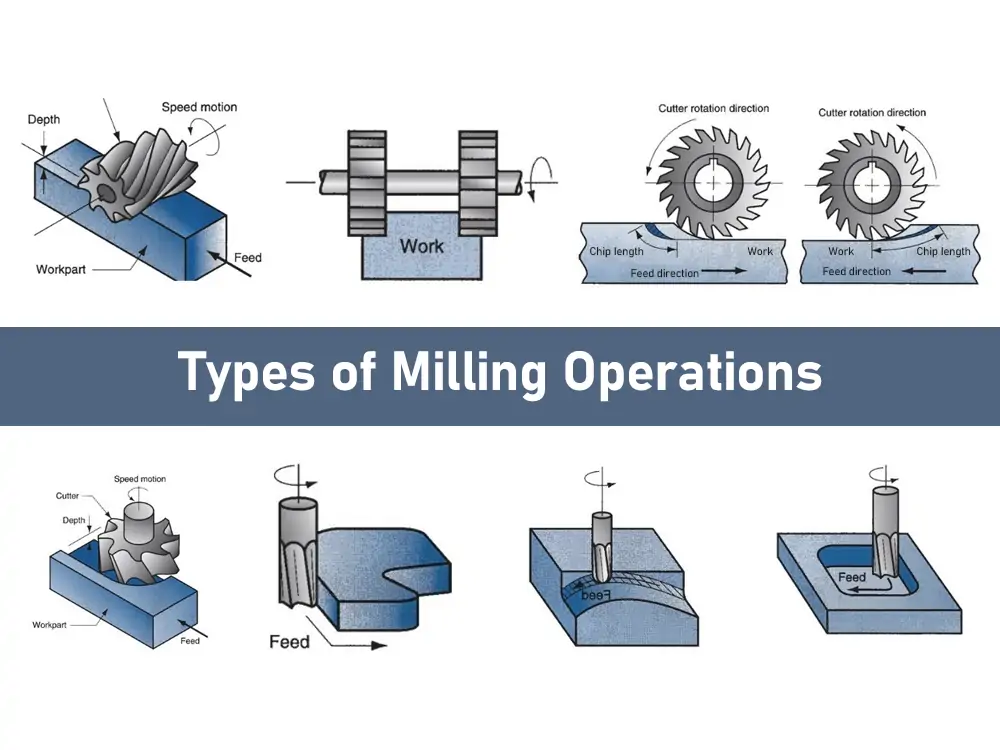

Overview of CNC Milling Operations

Now that we’ve explored the fundamentals, let’s move on to the operations themselves. CNC milling isn’t limited to one method of material removal. In fact, there are dozens of operations, but 12 are the most commonly used across industries.

Each type of milling operation serves a unique purpose. Some are designed for smoothing flat surfaces, others for cutting slots, and some for creating complex shapes like gears or threads. Choosing the right operation can make the difference between a successful project and wasted material.

Here’s a quick table summarizing some of the most common operations:

| Milling Operation | Description | Advantages | Applications |

| Face Milling | Flattens workpiece surfaces | High removal rate, smooth finish | Cylinder heads, heat sinks |

| Plain Milling | Creates flat surfaces & contours | Uniform removal, light machining | Outer layer machining |

| Side Milling | Machines the sides of a workpiece | Grooves, profiles, vertical surfaces | Suspension mounts, implants |

| Straddle Milling | Mills two parallel surfaces simultaneously | Efficient parallel slotting | Jigs, fixtures, gears |

| Gang Milling | Uses multiple cutters together | Multiple features at once | Engine blocks, transmission housings |

| Angle Milling | Cuts at specific angles | Precision angular cuts | Chamfers, T-slots |

| Form Milling | Produces irregular contours | Custom shapes | Turbine blades, implants |

| End Milling | Uses end mills for detailed work | Intricate profiles, smooth finishes | Precision parts, prototypes |

| Saw Milling | Large circular cutter slices material | Effective slotting, parting | Dividing workpieces |

| Gear Milling | Specialized for gear teeth | High accuracy | All gear types |

| Thread Milling | Cuts internal/external threads | Works well for large holes | Automotive, assembly components |

| CAM Milling | Makes CAM components for motion conversion | Precise shaping | CAMs in mechanical systems |

This overview gives us a snapshot, but to truly understand their value, we’ll need to break them down one by one. That’s what we’ll cover next.

Types of Milling Operations Based on Workpiece Geometry

When it comes to shaping materials, geometry is everything. Different operations are chosen based on whether you need flat surfaces, angular cuts, grooves, threads, or complex contours.

Let’s explore the most widely used operations in detail, starting with Face Milling.

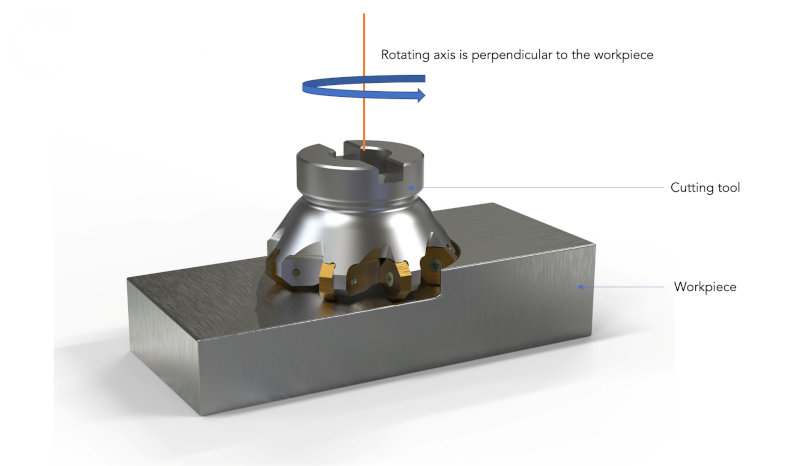

Face Milling

Face milling is often considered the “go-to” operation when manufacturers need a flat, smooth surface on their workpiece. In this process, the cutting tool’s axis of rotation is perpendicular to the surface of the workpiece. This orientation allows the sharp edges on the tool’s face and periphery to remove material efficiently while leaving behind a high-quality surface finish.

What makes face milling so powerful is its high material removal rate. The design of the tool allows it to cut across a broad surface in a single pass, making it excellent for removing excess material quickly. At the same time, it produces a smooth finish, reducing or eliminating the need for secondary finishing operations like grinding or polishing.

Face milling cutters typically come in two types:

Indexable insert cutters – These cutters use replaceable carbide inserts, making them ideal for heavy-duty work.

Solid carbide cutters – These are more expensive but provide excellent precision and durability for fine finishing.

Advantages of Face Milling:

Fast removal of large amounts of material

Smooth and uniform surface finish

Can be used on both small and large workpieces

Applications:

Machining automotive cylinder heads to create perfectly flat sealing surfaces

Manufacturing heat sinks for electronics, where smooth surfaces are critical for proper heat transfer

Creating flat bases for molds, dies, and fixtures in industrial production

Plain Milling

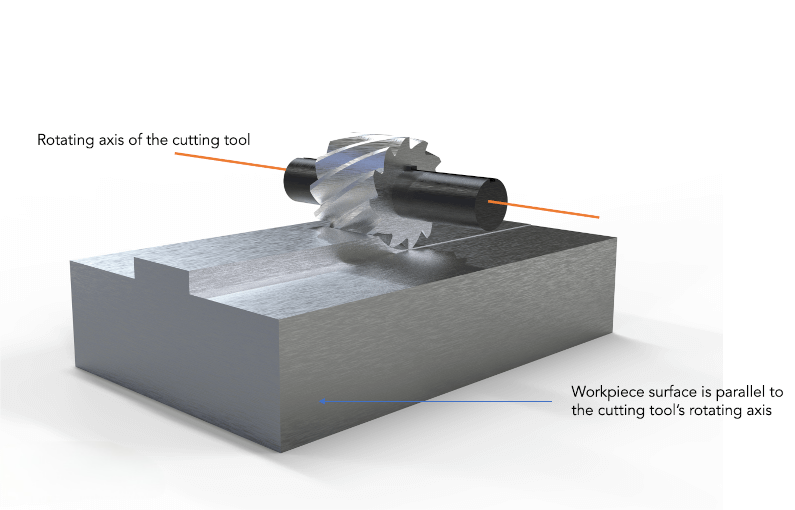

Plain milling, sometimes referred to as slab milling, is another widely used operation that produces flat surfaces. However, unlike face milling, the cutter in plain milling has its axis of rotation parallel to the workpiece surface. This orientation allows the cutter to remove material along the length of the workpiece.

The tools used in plain milling are cylindrical cutters with straight or helical teeth. Helical cutters are generally preferred because they provide smoother cutting action and less vibration compared to straight-tooth cutters.

Plain milling is particularly effective for light machining tasks. It doesn’t usually remove large amounts of material quickly, but it ensures uniform removal across the surface, making it ideal for preparing a part for further operations.

Advantages of Plain Milling:

Produces uniform flat surfaces and stepped surfaces

Good for machining contours and shallow slots

Lower cost compared to more complex operations

Applications:

Removing the outer layer of raw material from a workpiece before precision machining

Creating flat bases on large plates and sheets

Producing simple contours and preparing stock for advanced milling

Side Milling

Side Milling

As the name suggests, side milling focuses on machining the sides of a workpiece. It uses cutters with cutting edges on the periphery to create grooves, slots, or vertical flat surfaces. Side milling can be performed on both vertical and horizontal milling machines, depending on the orientation of the spindle.

The cutters used are typically side-and-face cutters or end mills with helical flutes. These cutters are designed to cut with their sides rather than their tips, making them ideal for shaping edges and slots.

What makes side milling versatile is its ability to create complex contours and features like T-slots, fins, and channels. Unlike plain or face milling, which focus mainly on the top surface, side milling lets manufacturers tackle edges and sides, expanding the design possibilities.

Advantages of Side Milling:

Excellent for creating slots and grooves of varying depths

Can produce intricate side features on components

Suitable for machining both soft and hard materials

Applications:

Automotive suspension mounts that require precise slots and edges

Aircraft structural components where weight-reducing grooves are critical

Medical implants like joint replacements, which require fine edge details

Heat sinks and cooling fins in electronics

Straddle Milling

Straddle Milling

Straddle milling is a unique process because it machines two parallel surfaces at the same time. This is achieved by mounting two side cutters on a single arbor, spaced at the required distance apart. As the workpiece moves forward, both cutters remove material simultaneously, leaving behind two identical parallel surfaces.

This operation is particularly valuable for saving time and ensuring symmetry. Instead of milling one side at a time and risking uneven spacing, straddle milling guarantees uniformity in one setup.

Advantages of Straddle Milling:

Reduces machining time significantly

Ensures precise spacing between two surfaces

Ideal for producing multiple identical profiles in bulk

Applications:

Manufacturing jigs and fixtures used in production lines

Creating brackets, levers, and gears with parallel slots

Machining axle housings and transmission components in the automotive industry

Producing sprockets and mechanical linkages

In industries where precision and speed are equally important, straddle milling proves to be an invaluable operation.

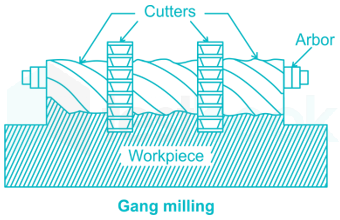

Gang Milling

Gang Milling

Gang milling takes the concept of straddle milling even further. Instead of using just two cutters, multiple cutters of different types are mounted on the same arbor. This setup allows several operations to be carried out in a single pass. For example, one cutter might create a slot, while another shapes an edge, and yet another flattens the surface—all simultaneously.

This approach greatly reduces machining time and increases efficiency, especially when producing parts with multiple features. However, gang milling requires careful setup and precise alignment, as all cutters must engage correctly with the workpiece at the same time.

Advantages of Gang Milling:

Multiple operations completed in a single setup

High efficiency and reduced cycle times

Cost-effective for mass production

Applications:

Engine blocks and transmission housings in automotive manufacturing

Frames and brackets requiring multiple features

Gears and sprockets that need various slots and contours

Die prototyping and tool manufacturing where complex features must be created quickly

Gang milling showcases the full power of CNC automation, turning what would normally require multiple operations into a streamlined, single-pass process.

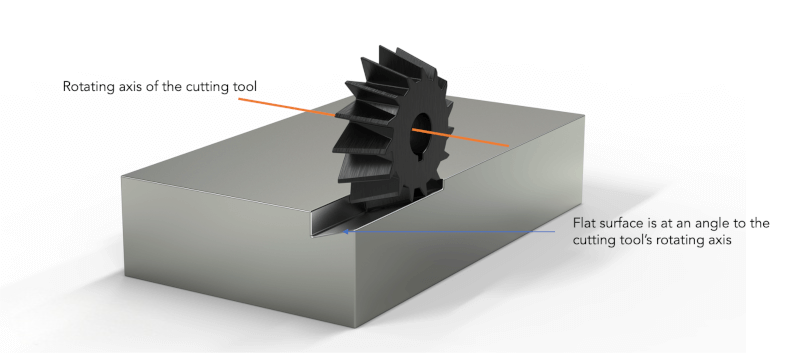

Angle Milling

Angle Milling

Angle milling is the process of cutting a workpiece at a specific angle other than 90°. Unlike face or plain milling, where surfaces are machined flat, angle milling allows the creation of slanted, beveled, or angular features. This is achieved by using either single-angle or double-angle milling cutters.

For example, a single-angle cutter might be used to cut a 45° chamfer, while a double-angle cutter could create a V-shaped groove. Angle milling operations are often performed with the help of fixtures or angle plates that hold the workpiece at the correct orientation.

Advantages of Angle Milling:

High precision in creating chamfers, bevels, and angled slots

Ability to produce T-slots and dovetail slides commonly used in machine tool design

Flexibility to cut both fixed angles (like 45° or 60°) and custom angles

Applications:

Machining T-slots on machine beds, where fixtures and clamps are mounted

Creating dovetail slides for tools, which allow smooth linear movement

Adding chamfers and bevels to components for both functionality and aesthetics

Manufacturing complex joints used in mechanical systems

Angle milling is widely used in toolmaking, die manufacturing, and industries that require precise angled features.

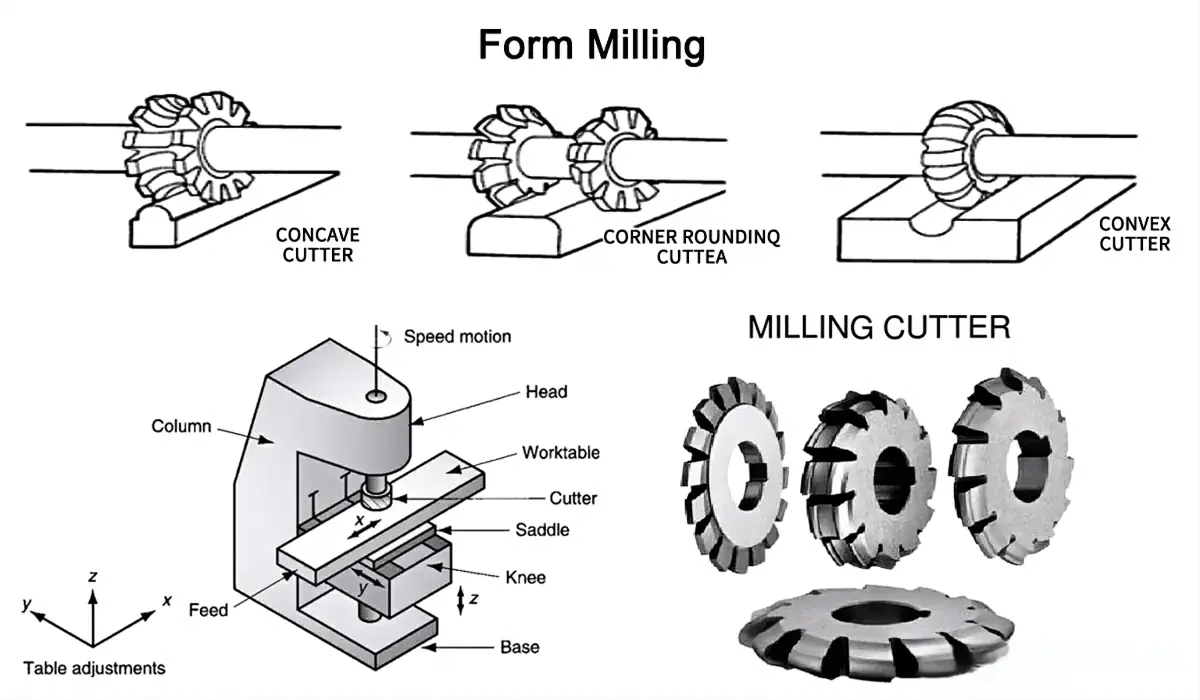

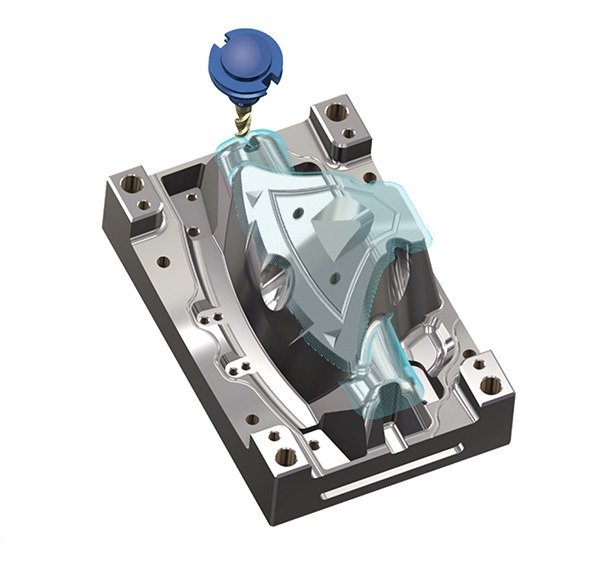

Form Milling

Form milling is all about shaping irregular contours and complex surfaces. Unlike basic operations that produce flat or simple geometric features, form milling employs cutters shaped as the negative profile of the desired contour. When the cutter rotates across the workpiece, it produces the intended 3D geometry.

This technique is perfect for parts that require unique shapes, curves, or intricate details. Since the cutter itself carries the profile, the machine doesn’t need advanced multi-axis movements to achieve complex contours.

Advantages of Form Milling:

Ability to produce highly customized and irregular shapes

Reduced need for multiple operations since one cutter can create a complete profile

Precision shaping of complex surfaces with minimal errors

Applications:

Turbine blades in aerospace, which require aerodynamic curved profiles

Orthopedic implants such as knee and hip joints, designed to match human anatomy

Dome-shaped pistons in automotive engines

Custom prototypes and molds for product development

Guitar bodies and artistic components, where aesthetics are as important as function

Form milling highlights the versatility of CNC technology, transforming raw materials into parts with both functional and artistic value.

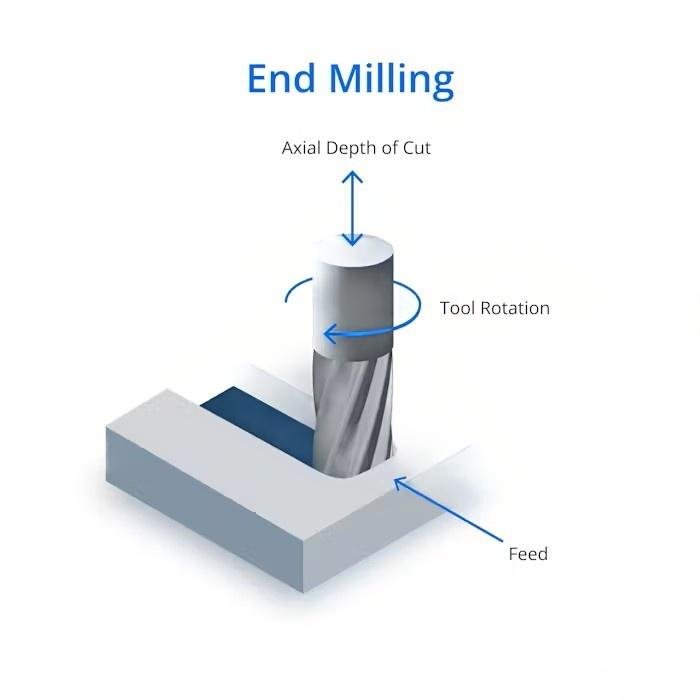

End Milling

End Milling

End milling is perhaps the most versatile and commonly used CNC milling operation. It employs end mills—cutters with multiple cutting edges on both the tip and sides. This dual-action cutting allows the tool to shape the workpiece in many ways, including creating profiles, slots, pockets, and intricate surface details.

End mills come in different varieties, such as:

Flat end mills – For creating sharp-edged profiles and slots

Ball nose end mills – For curved surfaces and 3D contouring

Corner radius end mills – For producing rounded edges and preventing chipping

What sets end milling apart is its ability to machine with precision and flexibility. Whether you need fine grooves, deep slots, or smooth surface finishes, end milling can handle the task.

Advantages of End Milling:

Exceptional flexibility for producing a wide range of geometries

High accuracy for detailed machining

Capable of producing smooth surface finishes and sharp edges

Applications:

Precision components in electronics and medical devices

Tool and die making, where detailed cavities and slots are needed

Automotive parts like engine housings and mounts

Prototyping of complex designs in various materials

Because of its adaptability, end milling is considered the workhorse of CNC operations.

Saw Milling

Saw milling is a specialized operation that uses a large circular cutter with teeth around its circumference to slice through a workpiece. Much like a saw in woodworking, this process is perfect for creating narrow slots, dividing material into sections, or parting off components.

Although slower compared to other milling techniques, saw milling is very effective when precise slots or separations are required. One challenge with saw milling is heat generation—because of the cutter’s size and depth of cut, the process can create friction that leads to thermal stress on both the tool and the workpiece.

Advantages of Saw Milling:

Ideal for cutting deep, narrow slots

Effective for parting off large sections of material

Can produce straight cuts with minimal material waste

Applications:

Creating slots in gears or pulleys

Dividing large workpieces into smaller parts

Cutting grooves in mechanical assemblies

Producing profiles or slight curves in specialized components

Despite its limitations in speed, saw milling remains a reliable operation where precision slots and divisions are necessary.

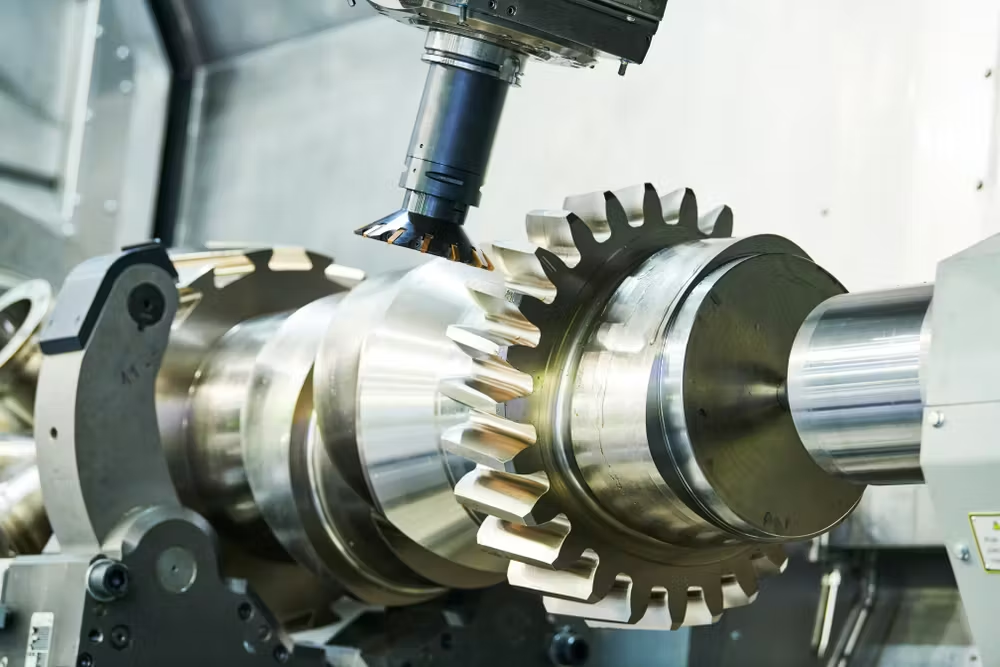

Gear Milling

Gear Milling

Gear milling is a specialized operation dedicated to the production of gears. Unlike general milling processes, this operation requires specially designed gear cutters or gear hobbing tools. These cutters shape the teeth of the gear to precise dimensions, ensuring proper meshing with other gears in mechanical systems.

The accuracy required in gear milling is extremely high, as even the slightest deviation can lead to inefficiency, noise, or mechanical failure. CNC gear milling ensures that gears are manufactured with consistent tooth profiles and surface finishes.

Advantages of Gear Milling:

High precision in cutting gear teeth

Ability to create gears of various types: spur, bevel, helical, or rack-and-pinion

Flexibility to refine pre-formed gears or manufacture new ones from scratch

Applications:

Automotive transmissions, where gears control speed and torque

Industrial machinery, including conveyors and heavy equipment

Aerospace systems, where lightweight yet precise gears are critical

Robotics, requiring compact gears with accurate meshing

Gear milling is often considered one of the most costly operations, but its importance cannot be overstated—it literally keeps machines moving smoothly.

Thread Milling

Thread milling is a highly efficient method for cutting both internal and external threads on a workpiece. Unlike tapping, which is limited to cutting internal threads with a fixed-size tool, thread milling uses specialized thread mill cutters that allow greater flexibility.

In thread milling, the tool follows a helical path, gradually carving the thread into the material. This method is especially useful for large-diameter holes, where taps would be impractical or prone to breaking.

Advantages of Thread Milling:

Flexibility to cut different thread sizes with one tool

Produces high-quality threads with better surface finishes than tapping

Lower risk of tool breakage compared to tapping

Ability to cut both left-hand and right-hand threads

Applications:

Automotive engines, where threaded holes are essential for assembly

Consumer electronics, requiring precision threads for fasteners

Industrial machinery, with large threaded holes for assembly parts

Aerospace components, where high-strength threaded joints are critical

Thread milling has become a preferred choice in industries that require precision threading and versatility.

CAM Milling

CAM Milling

CAM milling is used to produce cams, which are mechanical components that convert rotational motion into linear motion—or vice versa. These are essential in machinery such as engines, automation systems, and textile machines.

The process involves using a dividing head tool to rotate the workpiece while the cutter removes material according to the cam’s profile. Because cams often have irregular shapes, this operation requires extreme precision to ensure smooth motion in the final application.

Advantages of CAM Milling:

High accuracy in creating cam profiles

Ensures smooth motion transfer in mechanical systems

Customizable for different cam designs and functions

Applications:

Automotive camshafts, which control the opening and closing of engine valves

Textile machinery, requiring cams for repetitive motion cycles

Automation equipment, converting continuous motion into programmed movements

Mechanical clocks and devices, where cams regulate motion cycles

CAM milling is highly specialized but crucial for industries that rely on motion conversion.

Types of CNC Milling Operations Based on Mechanisms

Manual Milling

Beyond the geometry of cuts, milling operations can also be classified by how they are executed. Three major categories stand out:

Manual Milling

In manual milling, the operator is responsible for setting up the workpiece, adjusting parameters, and moving the cutter. This gives flexibility for one-off parts or custom work but sacrifices speed and precision.

Pros: Low setup cost, flexible, ideal for prototypes

Cons: Time-consuming, less accurate, labor-intensive

CNC Milling

CNC milling automates the entire process using computer programs. Multi-axis CNC machines (3–6 axes) can handle complex geometries with unmatched precision.

Pros: High precision, repeatability, efficient for mass production

Cons: Higher setup cost, requires programming expertise

Conventional vs. Climb Milling

These two methods differ in how the cutter rotates relative to the feed direction:

| Feature | Conventional Milling | Climb Milling |

| Tool vs. Feed Direction | Opposite | Same |

| Surface Finish | Rougher | Smoother |

| Tool Wear | Higher | Lower |

| Material Removal | Lower efficiency | Higher efficiency |

| Best For | Softer materials | Harder, consistent materials |

Choosing the right mechanism depends on both material type and project requirements.

Factors to Consider When Choosing Milling Operations

With so many operations available, how do you decide which one is best for your project? Here are the main factors:

Material Type

Different materials behave differently under cutting forces. Hard materials like tool steel may require slower feed rates and specific cutters, while softer materials like aluminum allow faster machining.

Desired Surface Finish

Each operation delivers a unique surface roughness. For instance, face milling provides Ra 0.8–3.2 µm, while slot milling may only achieve Ra 1.6–6.3 µm. Matching your required finish to the right operation prevents extra finishing work.

Geometric Complexity

Simple parts may only need plain or face milling. But for intricate parts, such as gears or threads, specialized operations like gear milling or thread milling are essential.

Machine Parameters and Settings

Spindle speed, cutting depth, and feed rates directly affect both efficiency and finish. Multi-axis capabilities also open the door to more complex geometries.

Selecting the Right Cutter

Cutter choice is just as important as the operation itself. Flat end mills are great for sharp edges, while ball nose cutters excel at curved surfaces. Using the wrong tool can lead to poor results or tool damage.

Conclusion

CNC milling is more than just cutting metal—it’s a precision art combined with advanced engineering. From simple flat surfaces to intricate gears and threads, CNC milling offers operations tailored to every manufacturing challenge.

Each type of milling operation—whether it’s face milling for smooth surfaces, gear milling for precision teeth, or form milling for irregular contours—plays a vital role in modern production. Choosing the right operation, along with the right tool and machine parameters, ensures efficiency, accuracy, and cost-effectiveness.

As industries demand more complex and high-quality parts, CNC milling will continue to be at the heart of modern manufacturing.

FAQs

- What are the basic types of milling machines?

The two main types are horizontal milling machines(where the spindle is parallel to the ground) and vertical milling machines(where the spindle is perpendicular). - Which milling operation provides the highest precision?

Form millingis considered one of the most precise, as it uses a specially shaped cutter to directly produce complex contours with minimal errors. - Which milling operation is the most expensive?

Gear millingoften incurs the highest costs due to the need for specialized cutters, longer cycle times, and highly precise setups. - Which operation is the most cost-effective?

Plain milling(or slab milling) is the most cost-effective. It’s simple, requires fewer tools, and works efficiently on flat surfaces. - What is the main difference between CNC and manual milling?

Manual milling relies on human control and is better for custom, one-off parts. CNC milling is automated, faster, more precise, and ideal for mass production.