Are ferrous, and non-ferrous metals distinct? Well, the answer is No. Ferrous contains iron. Inversely, non-ferrous don’t. Ferrous metals are comparatively more rigid than nonferrous metals. Generally, they are employed in construction and heavy machinery. Oppositely, non-ferrous metals are weightless, and easily get eroded. In addition, these are non-magnetic, so less favorable for industrial usage. Let’s figure out some core aspects that set apart these metals.

What is a Ferrous Metal?

Ferrous metals primarily contain iron. They are typically recognized for high tensile strength. Due to exceptional toughness, these are employed in construction, huge pipe works, and industrial vessels. The intended properties imply that the ferrous metals are designed for a relatively long average life span.

The name ferrous is derived from the Latin word ferrum. These materials are highly appreciated for their corrosion endurance and strength. They are resistant to high or low temperatures. So, are highly beneficial for exploitation in electronic, and construction buildings. However, they can easily be prone to corrosion. So, the formation of an oxide(passive layer) on the surface is vulnerable if exposed to either moisture or oxygen.

What is Non-Ferrous Metal?

Nonferrous metals(no iron), help produce lighter and more ductile products. They can be recommended for use where lightness is a critical consideration and strength is required. For instance, the aerospace industry uses these metals in construction for efficiency and lightweight construction.

Owing to their unique properties, they are used extensively in applications that require low density, high electrical and thermal, and corrosion resistance.

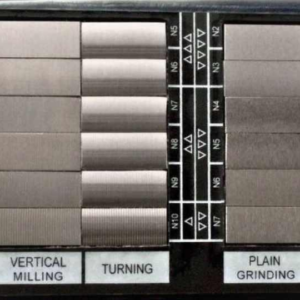

Ferrous Vs.Non-Ferrous Metals: Core Properties

The table below provides distinctions between ferrous and nonferrous metals. It includes their wear resistance, hardness, ductility, and uses in different sectors of the economy.

| Property | Ferrous | Non-Ferrous |

| Durability | Strong and long-lasting; perfect for construction and tools. | Highly resistant to wear; great for various applications. |

| Strength | Extremely strong; ideal for heavy machinery and railroad tracks. | Strong yet lightweight; excellent for precision components. |

| Malleability | Easily shaped; steel combines iron and carbon for versatility. | Lightweight and moldable; commonly used in aerospace. |

| Magnetism | Generally magnetic, which can limit some applications. | Mostly non-magnetic; preferred in electronics and wiring. |

| Corrosion Resistance | Susceptible to rust without protective coatings; requires maintenance. | Naturally resistant to corrosion; great for outdoor and plumbing uses. |

| Common Examples | – Mild Steel

– Carbon Steel – Stainless Steel – Cast Iron – Wrought Iron |

– Copper

– Aluminum – Lead – Silver – Brass – Gold |

| Cost and Availability | Widely available and generally more affordable. | Less common and typically more expensive; often classified as precious. |

Ferrous Metals: Key Examples and Their Features

Ferrous metals have a wide variety of specifications. Here are common ferrous metals with intended use:

Non-Alloy Steels

The largest category of steel is nonalloy or carbon steel. These are bred on iron and carbon components. However, non-alloy steel contains compounds like Sulfur, phosphor, silicone, and manganese but their concentrations are comparatively low. They do not affect material properties. Such structural steels include S235 and S355. Some common examples are low-carbon steels, medium-carbon steels, and high-carbon steels.

Low Carbon Steel

Low-carbon steels have 0.05% – 0.25% carbon content. They are relatively cheap and easily shaped. They are well suited for use in a manufacturing setting. These steels are applied in bolts, nuts, and different medium-loaded parts. Some examples include C10E (1.1121) and C15E (1.1141).

Medium Carbon Steel

These steels contain a carbon % between 0.25 – 0.6%. The supplementary carbon improves the combination of strength and hardness in steel. These steels are ideal for automotive parts such as gears, axles, and shafts. The examples of such compounds are C40E (1.1186) and C60E (1.1221).

High Carbon Steel

High-carbon steels have a carbon content of between 0.6 % to 1.0%. These are the strongest of all ferrous materials. They are exemplary where wear is a typical concern, such as; in tools and springs. Their weldability and ductility are less than lower-carbon steel. Some examples include C70U (1.1520) and C105U (1.1545).

Steels and Alloying Elements

Simplified, alloy steels contain other ingredients such as chromium, nickel, silicon, and titanium among others to improve some characteristics. These elements have a considerable effect on mechanical properties.

- Chromium: Chromium improves the SS corrosion properties. Additionally, it raises its hardness and tensile strength.

- Manganese: The manganese improves SS’s ability to be formed into thin sheets. Moreover, it imparts strength and quenching of stainless steel.

- Nickel: Nickel increases the toughness and corrosion resistance of stainless steel

- Silicon: Augmenting material with enhanced elasticity, especially in the case of springs.

- Titanium: Strengthens and restricts grain size to increase corrosion performance.

- Molybdenum: Improves mechanical characteristics and the resistance to corrosion at high temperatures.

Cast Iron

Cast iron alloy, generally has 1.5-4% of carbon content. Also, it contains Si, Mg, sulfur, and phosphorus. Due to its peculiar composition, its use is common in the production of engine blocks and cookware.

Non-Ferrous Examples Overview

Let’s brief out some of the common non-ferrous metals and their characteristics.

Copper

Copper is used in the manufacturing of roofs, electrical wiring, and water pipes. It possesses a thermal conductivity capacity of up to 400W/m.K and an electrical conductivity of nearly 59.6 MS/m. Copper is easily deformable. Moreover, it can be stretched over 40% to get the desired shape. Its tensile strength varies between 210 and 600 MPa.

Aluminum

Aluminum is a weightless metal. It has a density of about 2.7 g/cm³. Mostly employed in aircraft, automotive components, and packaging. Aluminium has a melting point of 660°C. Ai has different tensile strengths depending on the alloy type. Typically, ranges from 90 to 700 MPa which makes it flexible, and durable for use.

Lead (Pb)

It is a soft, easily deformable metal. Mainly adopted for making batteries and shielding against radiation and pipes. Lead has a low melting point of 327.5°C and is very immune to many acids. The tensile strength values of lead range from 12 to 17Mpa.

Zinc

It has been used in the dip–coating process and die-casting process with steel. It has a melting point of 419.5°C. In addition, zinc offers adequate anti-corrosive coatings. Zinc tensile strength of about 100 – 150 MPa makes it optimal and best suited for use in protective coatings.

Tin

It is malleable and usually used to overlay steel and in making bronze. Tin is relatively easy to work with. Its melting point is 231.9 degrees Celsius. Tin has a low tensile strength of between 10-40 MPa. Ideally, tin is employed for flexibility-demanding applications.

Applications of Ferrous Metals and Non-Ferrous Metals

Although ferrous metals can not be polished. They are vital in the production of nuts, bolts, and shipping containers. Further, these metals are used widely in manufacturing rail tracks and train parts besides, used in automotive parts production.

Corrosion resistance is a primary reason why nonferrous metals are generally favored. They are mostly used in architectural and design projects, where product aesthetics matters. Some common examples include elevators, aerospace industries, and electronics because they are light in weight and powerful. Through such uses, industries can determine the right metal to use in the right application to make the metal efficient and performant.

Final Thoughts

Iron/Ferrous and noniron/non-ferrous are used in different capacities in industrial settings. Ferro’s category of metal includes iron features, high strength, and wear resistance. So, mainly finds extensive use in construction, automotive, and manufacturing industries. Nonetheless, they are prone to rusting and corrosion. Non ferrous on the other hand contain minimal or no iron at all. They are highly resistant to corrosion and weightless. These metals are widely used in the aerospace industry, electronics, and architecture. Because these sectors demand strength and beauty. Thus, it’s essential to understand the differences, that exist between the different metal types to arrive at the most ideal solution for a given task.

FAQs

Q1. Mention some examples of non-ferrous metals.

The primary examples are aluminum, copper, lead, and zinc. They are appreciated due to their lightweight, high ability to resist corrosion, and highly conductive nature.

Q2. How do ferrous, and Non-ferrous metals differ?

The primary difference lies in their iron content. Nonferrous means no iron, while ferrous has consistent iron. This affects other features such as corrosion ability which defines their usage in certain areas of application.

Q3. How do these metals influence the recycling processes?

Ferrous metals are generally magnetic. This property makes it easy to sort them during recycling. Non-ferrous metals, however, do not have this magnetic quality. As a result, they require different techniques for collection and processing.

Q4. Is stainless steel ferrous or nonferrous?

Yes, stainless steel is a ferrous metal. Typically, it is made of 50% to 70% iron, depending on grade-specific. The remainder includes nickel and chromium elements.