Silk screen printing on metal transfers designs onto metal surfaces. It uses a mesh screen to push ink. The technique helps you create sharp and durable prints. Moreover, it is ideal for signage and parts. Silk screen printing ensures vibrant, long-lasting colors.

In this guide, you will get insights about the silk screen printing process, the materials used, and the benefits it brings to your project. So, let’s get into it.

Silk Screen Printing Process on Metal

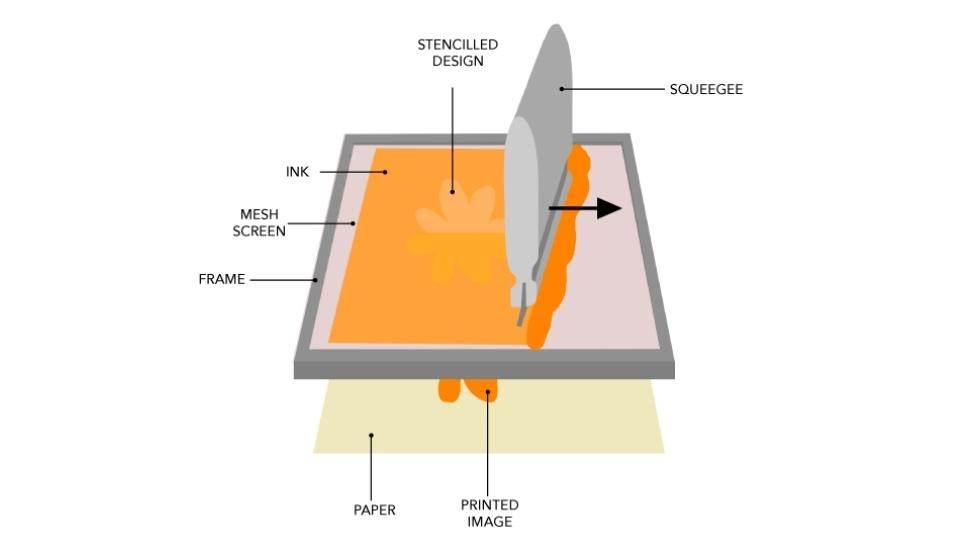

Illustration of the silk screen printing process on metal, showing key steps and silk finish

The process steps are given below:

1. Preparing the Screen

First, use a degreaser to wipe the screen in case, it is covered with dust or other impurities. Simply, clean away any ink or leftover residue present on the surface. Then, uniformly expose a light-sensitive emulsion onto the screen. Let the prepared emulsion dry in a dark room.

The screen must be dry completely for proper exposure. Ensure, you do not expose the screen to any more dust particles when applying the screen coat, let it dry. Once dry, the screen is ready for the design.

2. Creating the Design

Sketch your design on a computer by using design software. Ensure your design is in high resolution for clarity. You need to use a printer to print the design on clear film material with high image quality.

Next, position the film on the screen top, and place it correctly. Take the screen, place it under UV light, and keep it for a certain amount of time. The light will cause the emulsion to become fixed where it is with the design and the rest area will remain untouched. The exposed areas will remain soft and can be washed away.

3. Preparing the Metal Surface

To clean the material from the oils and dirt use a solvent cleaner or abrasives. The metal must be free from contaminants. Dampen the surface with clean soapy water then rinse the surface again with a fresh cloth then use a clean, lint-free cloth to wipe it dry. However, for some metals, a primer may be applied to aid the adhesion of the ink. The next step can only be done after the primer has had time to dry. Make sure the surface is smooth to allow the proper ink application.

4. Screen Aligning

When placing the screen bring it over the metal surface carefully. If you find your design is off use the registration guide to get it back into the right position. Stabilize the screen by hammering clips or you can use a printing machine.

In addition, make sure the two are correctly aligned and do not shift in the course of printing. The appropriate alignment helps to achieve accurate and clear prints on the paper. If pressure is required you ought to modify the screen elevation. When the screen and the frame are configured, the screen is prepared for printing.

5. Applying the Ink

Apply a generous amount of ink to one side of the screen. Use a squeegee to push the ink across the screen stencil. Further, make sure that pressure is firm and straight down and up to promote ink bleed onto paper. Go from one end to the other and paint the exterior design part.

Then, the link will pass through the mesh onto the metal plate. Repeat this until the wave has the desired, and consistent coverage. When the printing is accomplished, the screen must be cleaned so that the ink will not dry up on its screen.

6. Curing the Print

Ink will dry in a shorter time after printing. Therefore, it’s right to let it dry for some time after printing. A conveyor dryer is useful for curing the print while you can also use the oven to cure the print. The heat methods help to guarantee that the ink sticks to the metal strongly. Drying time and temp are different for different ink types. In this case, check the print for brightness and rub fastness. Incidental curing also complements the improvement of the design’s durability.

Popular Applications of Silk Screen Printing on Metal

- Signage

- Automotive Parts

- Industrial Equipment

- Decorative Metal Products

- Electrical Panels

- Nameplates

- Control Panels

- Appliance Labels

- Printed Circuit Boards

- Building Facades

Suitable Metals for Silk Screen Printing

Achieving Precise Color Matching with Metal Silk Screen Printing

The metal silk screen printing method helps your projects get the best color-matching results. When you use good quality ink, the chance of getting a good shade and consistency throughout your many pieces is frequently high. Moreover, it provides precise control when it comes to the ink deposition on the material surface, which results in a good color yield.

In addition, the silk metal printing service is optimal for logo design, complex patterns, and images since silk screen printing offers high quality with fine lines and clear and clean colors. In addition, it becomes possible to match Pantone, and any other color necessary to meet the specific brand identity. So, It remains highly reliable and as such preferred by businesses that require high standards in prints on metal.

Silk Screen Printing vs. Heat Press Printing: Key Technical Aspects

Let’s figure out the distinctive aspects of silk screen printing vs. heat press printing.

| Factors | Silk Screen Printing | Heat Press Printing |

| Printing Process | Uses mesh screens to apply ink directly to the surface. | Transfers designs using heat and pressure from transfer paper. |

| Material Compatibility | Ideal for rigid materials like metal, wood, and glass. | Best for flexible materials like fabrics and ceramics. |

| Durability | Highly durable, resistant to fading, cracking, and peeling. | May wear faster, especially on fabrics. |

| Color Precision | Requires separate screens for each color; less ideal for complex designs. | Allows full-color printing, perfect for detailed images. |

| Setup Time and Cost | Higher setup time and costs, especially for multi-color designs. | Lower setup costs and faster for smaller runs. |

| Print Finish | Creates a thicker, more tactile finish. | Results in a thinner, more flexible print. |

Industries Where Silk Screen Printing is Used

Here are the common consumers of silk screen printing:

Automotive Industry

Silk screen printing marks automotive parts with precision. It applies durable logos and instructions. The prints resist heat, UV, and chemicals. Ideal for long-lasting automotive components like dashboards.

Electronics Industry

In electronics, silkscreen prints PCBs and keypads. Precise labeling enhances identification and functionality. It withstands wear and tear in electronics. Durable prints ensure legibility in devices.

Manufacturing Sector

Silk screen printing labels machinery and metal parts. It provides sharp, long-lasting markings on equipment. Durable prints withstand tough working conditions. It’s ideal for appliance labeling and equipment identification.

Signage and Advertising

Silk screen printing creates metal signage and billboards. It produces vibrant, weather-resistant prints for outdoor use. Colors remain bold, even under direct sunlight. It’s perfect for eye-catching promotional displays.

Textile Industry

Silk screen printing is used for fabric designs and logos. It applies vibrant colors that last long. Prints resist fading, even with washing. It’s ideal for apparel branding and graphics.

Construction and Architecture

Silkscreen prints safety signage and metal panels. Durable prints withstand outdoor elements and harsh conditions. It’s ideal for building facades and decorative products. Prints stay sharp and clear over time.

Packaging Industry

Silk screen printing marks product labels and boxes. It makes sure of durable branding for packaging materials. The prints endure handling, transport, and retail displays. Therefore, It’s ideal for barcodes and product information.

Factors Affecting the Cost of Screen Printing

Below are a few factors that contribute to the cost of screen printing:

Setup Fees

The expenditures involved in the initial setup are in preparing the screens, emulsion, and equipment. Additional intricacies in designs or different colors add to the cost of setup.

Material Costs

The price of the ink type used, the size of the screen mesh, and the metal type are the core determinants of the cost. Ink quality and metal quality increase cost; since they are related to price increases.

Quantity of Prints

In the unlimited production size, the total cost is expected to be lower than the cost per unit of part production as per the principle of economies of scale. The small batch runs may be costly compared to the normal production per piece.

Design Complexity

As we all know, elaborate works that comprise several colors or special objects painted are time-consuming and tend to incur higher expensive.

Labor Costs

The cost of setup, printing, or curing with skilled labor can be a challenge for some companies. Conventional printing usually requires more time as opposed to the use of printer technology.

Curing and Drying Expenses

The cost of curing is influenced by the technique employed which could be an oven, or conveyor dryer, and the hours it takes the board to cure properly.

Post-Printing Processes

Further processing such as coating, cleaning, or finishing is also considered to be an extra expense. This pricing includes customized packaging or special handling.

What Type of Ink Is Used to Print Silk Screens on Metal?

The Image is a depiction of various ink types for silk screen printing on metal, including different color options

Silk screen printing on metal typically uses four main types of ink:

- Plastisol ink

- UV ink

- Water-based ink, and

- Solvent-based ink

Plastisol ink is the most popular type, characterized by its full coverage of the substrate material and highly saturated colors.

UV ink dries instantly under ultraviolet light, which gives the printed material high protection from scrapings, chemicals, and heat. It is particularly suitable for those who require their prints to last longer. For example in a car part or metal body.

Aqua-ink is more environmentally friendly. It provides a less abrasive coating and is normally employed in decorative metal products.

Finally, solvent-based ink provides high adhesion. These are suitable to be used in industrial labeling on devices made of metal.

If you’re looking for a reliable, one-stop solution for your silk screen printing needs on metal, Tops Precision is here to help. Reach out to us today for all your printing solutions!

Frequently Asked Questions:

Q1. What makes plastisol ink ideal for printing on metal?

Plastisol ink is thick and durable, providing excellent adhesion to metal surfaces. It resists cracking, peeling, and fading, making it perfect for long-lasting prints on metal.

Q2. How does UV ink differ from other silk screen printing ink?

UV ink cures quickly under UV light, offering fast production and superior resistance to heat, chemicals, and UV exposure, making it ideal for outdoor metal applications.

Q3. Can I Use water-based ink be used for all metal surfaces?

Water-based ink works well on many metal surfaces but may not adhere as effectively to smooth or glossy metals, requiring proper surface preparation.

Q4. Why choose solvent-based ink for industrial metal products?

Solvent-based ink offers strong adhesion and is highly resistant to moisture, heat, and chemicals, making it perfect for durable industrial metal products.