Here’s what our service includes and sets us apart:

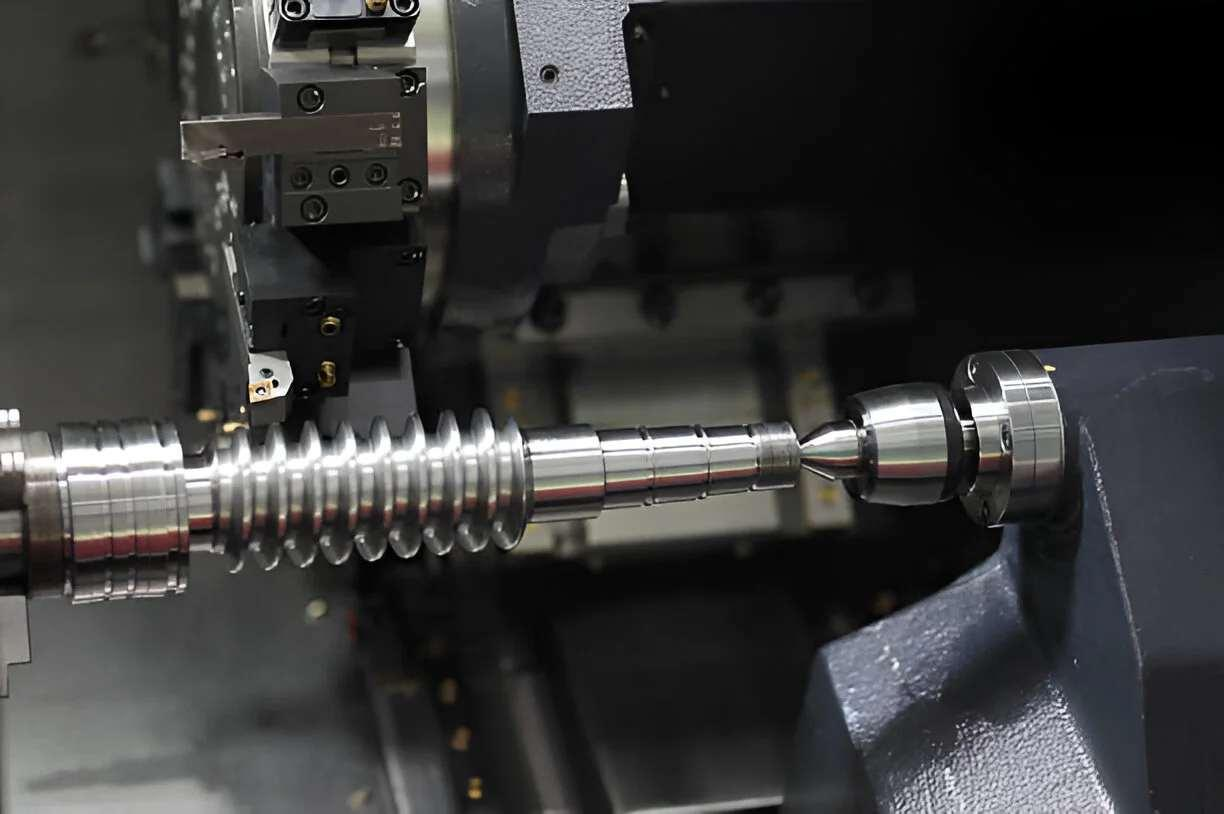

- ISO 9001:2015 certified CNC machining for OEM bicycle parts;

- Advanced 3, 4, and 5-axis CNC machines for accurate and complex parts;

- Supports bikes of all types, from off-road to high-performance models;

- Machining available for materials like aluminum, stainless steel, steel, titanium, brass, bronze, copper, zinc, ABS, acrylic, PTFE etc.;

- CNC milling and turning machining with tight tolerances up to ±0.400 mm;

- Machining for parts up to 90 mm in size;

- Horizontal milling for parts up to 18 x 22 x 12 inches, and custom designs;

- Turning for parts with up to 13-inch diameters.

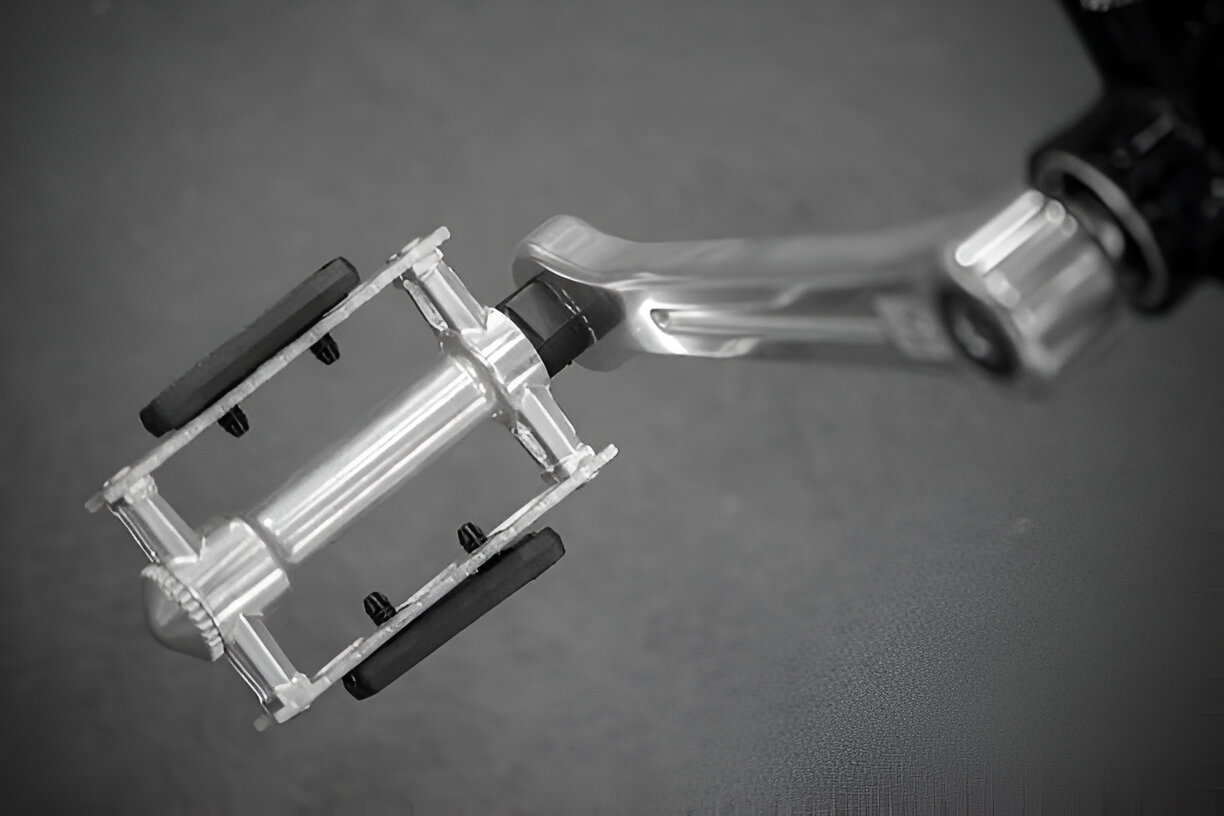

We make everything from lightweight stems and hubs to custom dropouts and spacers. Every part is made with meticulous care, and we don’t compromise on quality.

Send Your Inquiry Today

Why Prototyping and Fast CNC Machining Matters for Bicycle Parts

In the development of motorcycle and bicycle parts, prototyping and fast production play a major role. CNC machining at Tops Precision converts your CAD drawings into working parts in a short lead time. You get accurate samples, can test fit, and feasibility early, and proceed with confidence.

Our team assists you in avoiding long hours and reducing lead times, solving design issues in a short period, and eliminating expensive tooling requirements. This comes in particularly handy with custom frames, suspension parts, brackets, or fittings. You do not have to wait weeks; in fact, you receive parts in days. Besides this, the prototyping process is time-saving and keeps your project on schedule when speed, accuracy, and feedback are imperative.

Why Prototyping Matters in Early Development

Initial prototypes aid you in verifying fit, functioning, and geometry. It allows you to witness the part functionality before going into full production. When something is wrong in design, it becomes simple to make it right and make several attempts.

At Tops Precision, we machine your parts directly from your CAD files. You have working samples of the same size and material as the final. No 3D prints or guesses-just real parts for testing. This comes in handy with components such as dropouts, disc mounts, or linkages where the precision up to millimeters counts.

How Rapid Manufacturing Speeds Up Production

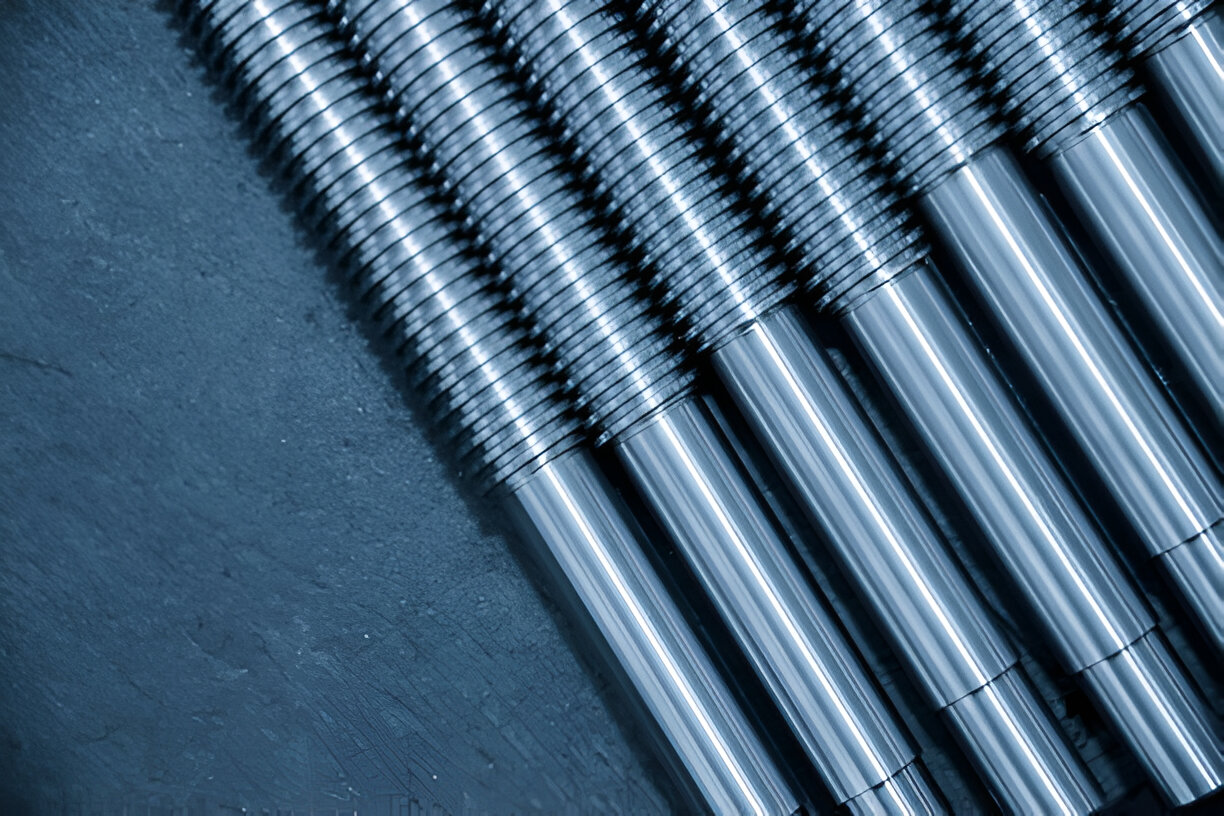

You do not always have the time to wait until full tooling. Swift CNC manufacturing keeps you on track. It can be used in short runs, a pre-production sample, or an emergency replacement.

We do not delay low to mid-volume batches. Need 5 stems next week? Or 10 brake mounts to test? We can provide rapid solutions without altering your design. This keeps your timeline flowing and lowers the risk at the time of launch.

Better Control Over Revisions and Small Changes

Designs are subject to post-testing. Our quick machining is capable of updating at a rapid pace. You stay in control of the part, the fit, and the finish.

Tops Precision synchronizes your files and creates the version that follows without slowness. You do not spend much time in back-and-forths or retooling.

Send Your Inquiry Today

Excellent CNC-Machined Bicycle Parts We Manufacture

At Tops Precision, we produce a wide range of precision CNC-machined bicycle parts. Each part is carefully crafted to meet your exact specifications and measurements. We focus on strength, fit, and durability to help your bicycle perform at its best.

Here are some of the key parts we machine with special attention to detail.